The many faces of AI

Type “AI” into your browser and you will find it can mean many things: American Idol, Auto Install, Adobe Illustrator even the Asphalt Institute, the very organization publishing this magazine, where our team has been promoting better asphalt pavements since 1919, long before anyone imagined computers could think.

But here, we mean Artificial Intelligence, the technology already shaping our lives in ways we hardly notice. It is the voice assistant that reminds you to grab an umbrella, the algorithm that queues up your next Netflix binge, the recommendation that puts those shoes you glanced at into every ad, and the tool that politely finishes your sentences in email. It touches our music, our photos, our shopping, even our food delivery choices, quietly anticipating our needs with uncanny accuracy. And it is not fringe science anymore.

As of August 2025, ChatGPT alone draws nearly 700 million weekly users, making AI the most widely adopted digital tool in history. If it can transform our daily routines so seamlessly, imagine what it can do for the world of civil engineering.

AI in civil engineering: The why

Civil engineering has always been about solving big, messy, real-world problems. We build things that must survive traffic, time and the occasional act of nature while staying on budget and looking good in the process. But the job is getting harder. Infrastructure is more complex than ever. Highways, bridges, water systems and transit networks all talk to each other now. Sometimes they argue. Sometimes they overshare, like a family group chat you cannot mute.

That complexity means the old formula of experience, intuition and a good clipboard is no longer enough. We need data-driven decision-making where AI does more than store numbers. It makes sense of them. Picture a project engineer who never forgets a detail, never needs coffee and works around the clock without a single complaint. Not here to replace you, but to take the tedious parts off your plate so you can focus on the decisions that matter most. With the right data, AI can be that dependable teammate, turning massive datasets into real-time insights you can actually use.

The applications are everywhere. In construction management, AI predicts risks, keeps schedules on track, guides autonomous equipment, monitors safety and tracks materials in real-time. In structural engineering, it powers structural health monitoring, predicts failures before they happen and optimizes designs for both performance and sustainability. In transportation, AI runs smart traffic systems, streamlines freight and logistics, improves transit, enhances safety surveillance and is turning science fiction into reality with self-driving cars now navigating real streets, real traffic and even the occasional drive-through restaurant.

In geotechnical and environmental engineering, AI predicts landslides and floods, classifies soils and models groundwater behavior. In urban planning and smart cities, it designs infrastructure, optimizes energy use, manages connected vehicles and plans smarter public spaces. In design and simulation, AI supercharges generative design and Building Information Modeling (BIM).

Whatever your specialty, AI is not just knocking on civil engineering’s door. It has already stepped inside, picked up a hard hat and is ready to get to work alongside us. Civil engineering has always relied on human insight, creativity and judgment to keep people safe, make systems smarter and use resources wisely. AI does not replace that. It amplifies it, if we use it wisely and with purpose, giving us a powerful new tool to achieve those goals and one that never gets tired, never takes a coffee or lunch break and never steals your parking spot.

AI in pavement engineering and science

If civil engineering is the big picture, pavement engineering is one of the most important pixels. Roads and runways are where civil engineering meets the everyday lives of billions of people, and where traffic, weather, materials and budgets all collide. That is a lot of variables to juggle.

Enter AI. Everything we just talked about, from data driven decision making to real-time insights, is just as powerful, if not more, in the world of asphalt and pavements. AI is now driving advances in pavement performance prediction through machine learning models that forecast rutting, cracking, roughness and overall performance. Long-term performance models can combine traffic data, climate conditions and material behavior to give us a clearer picture of how pavements will age over decades.

When it comes to distress detection and optimization, AI powered computer vision systems can automatically detect and classify surface distresses such as cracks, potholes, and raveling. Drone- or vehicle-mounted image and video analysis can provide real-time diagnostics, helping crews respond before minor issues snowball into major repairs.

On the pavement management side, AI-driven decision support tools are enhancing pavement management systems to prioritize rehabilitation strategies, fine-tune maintenance schedules, and optimize life-cycle cost analysis. In construction, intelligent compaction systems and automated detection of construction anomalies using sensors and AI algorithms are improving quality control and catching issues before they compromise performance.

AI is also playing a role in recycling and sustainability by modeling environmental impacts using big datasets for greener pavements, and in structural health monitoring through embedded sensors that continuously track in-situ pavement conditions, issuing real-time alerts when anomaly detection algorithms spot trouble.

Think of it as giving pavement engineers an upgraded set of glasses. Instead of just seeing the surface, AI helps us look into the future to predict how a road will age, how traffic will affect it, and what adjustments today can prevent expensive repairs tomorrow.

And speaking of adjustments, one area where AI’s predictive and optimization powers are shifting into high gear is mix design. That’s where our next stop comes in, a case study from my time at the Virginia Department of Transportation (VDOT) showing how machine learning can turn balanced mix design into a science so precise, it might just make perfection nervous.

How AI may shape Virginia’s asphalt future – case study

Balanced Mix Design (BMD) has been one of the most talked-about evolutions in asphalt mix design over the last decade. Instead of relying purely on volumetrics like air voids and asphalt content, BMD puts mixes through performance tests that simulate real-world conditions, measuring their resistance to rutting, cracking, and other distresses. The idea is simple: design a mix that is balanced enough to resist multiple modes of failure, not just look good on paper.

In Virginia, this approach has taken on extra urgency because of one of the industry’s favorite three-letter acronyms: RAP, short for reclaimed asphalt pavement. However, VDOT, like many agencies, wants to responsibly increase the percentage of RAP in its mixtures without compromising performance. High RAP content can mean big cost savings and environmental wins, but it also changes the behavior of the mix in ways that volumetric design alone cannot fully predict. That is where BMD earns its keep, and now where AI is stepping in to take things to the next level.

VDOT’s approach to high RAP mixtures

Virginia has been refining its BMD specifications to ensure high RAP mixtures meet the same or better performance standards as conventional mixes. The state’s Accelerated Pavement Testing (APT) facility serves as the proving ground for this effort, enabling researchers to push pavement sections to their limits in a fraction of the time it would take on the open road.

For this case study, six surface mixtures were evaluated. Two mixtures had conventional RAP content (30%): one designed using traditional prescriptive Superpave methods and the other using BMD, both with typical binder grade PG 64S-22. Three mixtures had high RAP content (45%): one with PG 64S-22, one with PG 64S- 22 plus a rejuvenator, and one with a softer binder PG 58-28, all designed using BMD. The sixth BMD mixture featured 60% RAP with a softer binder (PG 58-28) and a rejuvenator. These mixtures were tested not only in the lab but also under full-scale traffic simulation at the APT facility, with wheel loads applied day and night until the sections revealed their strengths and weaknesses.

The challenges of BMD in practice

BMD is powerful, but it comes with challenges. First, there is the design process itself. Performance testing takes time, and if a mix fails, redesigning can mean more materials, more testing and more delays. Then there is production variability. Even if the design looks perfect on paper, actual production can vary due to differences in aggregate properties, moisture content, plant calibration and/or other factors. Identifying the key factors behind those variations is tricky because, in asphalt mixtures, everything interacts with everything else.

Where asphalt meets AI

To get a handle on these challenges, I led a joint research team from VDOT and Virginia Tech, and together we went all in during the 2020 APT project. The team built an unusually rich dataset, pulling together results from 648 specimens fabricated for quality acceptance and tracking 26 different mixture characteristics, covering everything from volumetrics and gradation to mechanical properties.

Along the way, we put each mix through three of VDOT’s go-to BMD performance tests under a range of conditions, including during mix design (lab-produced and lab-compacted), plant-produced and lab-compacted directly (known as non-reheats) and plant-produced mixes that were stored and reheated before compaction (known as reheats):

• Cantabro Test, where we measure Cantabro Mass Loss (CML) to see how well a mix can resist raveling. Think of it as a durability stress test.

• Indirect Tensile Cracking Test (IDT-CT), which gives us the Cracking Tolerance (CT) Index, basically a score for how well a mix can shrug off cracks.

• Asphalt Pavement Analyzer (APA) Test, where repeated wheel loads tell us the Rut Depth (RD) and how easily a groove might form under traffic.

With what pavement researchers and engineers would call a mountain of data (and what data scientists might call a modest hill), we decided it was time to let machine learning take a crack at it. The mission was straightforward: see if AI could spot patterns and relationships that a human armed with a spreadsheet might miss, and maybe even predict performance before the design is finalized, the first ton of mix is produced or a single wheel touches the pavement.

Smart mixes start here

Once the data was ready, we handed it over to the digital apprentices. We tested multiple machine learning models, including linear regression (LR), random forest (RF), extreme gradient boosting (XGB) and support vector regression (SVR). The goal was threefold:

• Predict performance indices from a mix’s properties.

• Identify which factors carried the most weight in those predictions; and

• Help make BMD decisions faster, smarter, and grounded in data.

To keep things lean, we used feature selection to drop the low-value predictors so the models could zero in on the variables that truly influence performance.

Teaching AI to speak asphalt

The machine learning effort focused on predicting three key BMD performance indicators: CML, CT Index and APA RD. For each property, 80% of the available data was used to train the models, and the remaining 20% was set aside to test and confirm how well the models could predict new results they had never seen before.

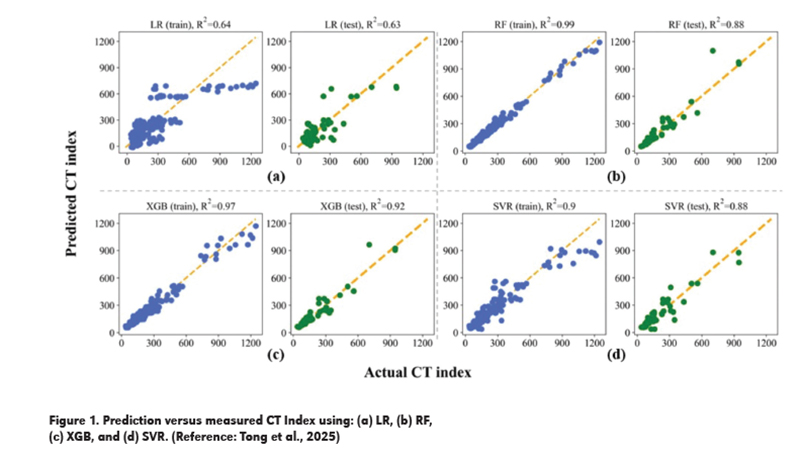

To keep things simple, imagine we’re looking at the CT Index as an example (refer to Figure 1). On the y-axis, you have the model’s predictions, and on the x-axis, you have the actual lab-measured CT Index values. Each machine learning model (LR, RF, XGB, and SVR) got its own plot. In each plot, the left side shows how the model performed on the training data, and the right side shows how it did on the testing data. Performance was evaluated using a standard statistic called the coefficient of determination RÇ, which measures how closely the predictions matched reality. The closer RÇ is to 1, the stronger the agreement between predicted and actual values.

Results told a clear story. RF, XGB, and SVR models consistently outperformed simple LR models, especially for CML and CT Index. APA RD proved more challenging.

Rutting behavior is shaped by a web of factors, and the relatively small dataset from APA testing added another layer of difficulty. Even so, the models uncovered insights that would be hard to capture with traditional analysis.

Finding the mix’s secret ingredients

One of the most practical advantages of machine learning is its ability to tell you which factors really drive performance. Using a permutation importance method on our best-performing models, we identified the “heavy hitters” for each BMD performance index.

For CT Index, the standouts were binder content, mix type (Superpave vs. BMD), material passing the No. 200 sieve, binder stiffness, and effective specific gravity (Gse).

For CML, the lineup shifted slightly to mix type, passing the No. 200 sieve, binder content, voids in total mix (VTM), passing the No. 8 sieve, and Gse.

For APA RD, binder content, binder stiffness, VTM, mix type, and material passing the No. 200, No. 30, and No. 8 sieves topped the list.

The bigger picture: Integrating AI into BMD

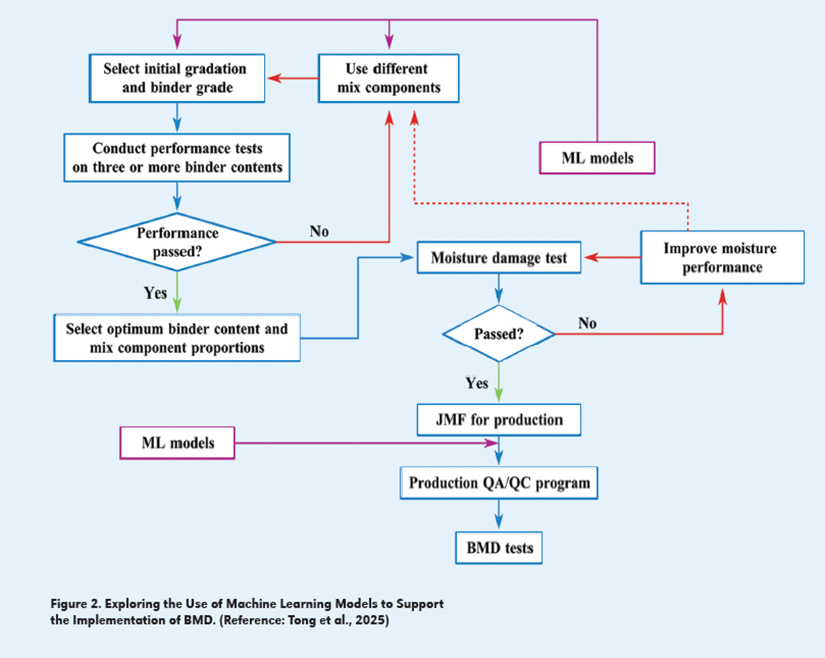

The ultimate vision is to weave machine learning into BMD workflows so that AI becomes a trusted advisor (refer to Figure 2). In the design phase, it could suggest adjustments before a single specimen is made. During production, it could flag when a mix is edging toward performance limits, prompting quick corrections. Over time, as more data is collected, models could be retrained to become even more accurate and predictive.

Of course, AI is not magic, and it will never replace the need for lab testing. Field-verified testing remains essential. What AI can do is help avoid misses, guide smarter decisions, and make work in the lab and plant smoother.

Think of it this way: traditional mix design is like planning a road trip with just a paper map. BMD adds GPS, giving you live traffic and route options. Adding machine learning is like having a co-pilot who has driven every road in the state, knows where the potholes are forming and can point you toward the best coffee stops. The engineer is still at the wheel, and AI just makes the ride smoother.

AI in pavements: Revolution or risk?

Like any powerful tool, AI in pavements sits at the intersection of promise and caution. On the revolutionary side, it opens the door to real-time pavement monitoring, predictive maintenance, smarter mix design, automated quality control, optimized use of recycled materials and even digital twins that model performance over decades. On the risk side, challenges loom such as data quality and bias, overreliance on algorithms, the “black box” problem, skill gaps, cybersecurity concerns and high implementation costs.

The bottom line is that AI will not replace the expertise, judgment, and lab testing that pavement engineering depends on, but it can supercharge them. Used wisely, it is less about replacing the human element and more about giving our industry a sharper, faster, and more reliable set of eyes on the road ahead.

Habbouche is an Asphalt Institute Regional Engineer based in Arizona.

Definitions

Artificial Intelligence (AI)

AI refers to computer systems designed to perform tasks that normally require human intelligence, such as solving problems, making decisions, or understanding language. In simple terms, if a computer seems like it is “thinking” or acting with some level of reasoning, you are looking at AI.

Machine Learning (ML) ML

is a core branch of AI. Instead of following step-by-step instructions, these systems learn from data, identify patterns, and improve their performance over time. Think of AI as the teacher setting the goal, and ML as the student who practices with the homework, learns from mistakes, and sometimes comes up with new insights on its own.

Linear Regression (LR)

Think of it as the “straight line” approach. It tries to draw a line through the data that best explains how changes in one thing (like RAP content) affect another (like cracking resistance).

Random Forest (RF)

A team of decision trees working together. Each tree makes its own prediction, and then they “vote” on the final answer. It’s like getting advice from many experts instead of just one.

Extreme Gradient Boosting (XGB)

A turbo-charged version of decision trees. It builds trees one at a time, each one learning from the mistakes of the last, until it gets really good at making predictions.

Support Vector Regression (SVR)

A boundary-setter. It draws a “margin” around the data and tries to fit a line within it, focusing on predicting values as accurately as possible while ignoring small, unimportant deviations.

References

“Machine Learning-Based Prediction and Optimization of Balanced Mixture Design Performance Indices”, Transportation Research Record, 2025, Tong, B., Huang, W., Habbouche, J., Boz, I., Guo, Q., Diefenderfer, S.D., and Flintsch, G.W.

“Evaluation of BMD Surface Mixtures with Conventional and High RAP Contents Under Laboratory-Scale and Full-Scale Accelerated Testing” Virginia Transportation Research Council, Report 25-R16, 2025, Habbouche, J., Tong, B., Flintsch, G.W., Diefenderfer, S.D., Diefenderfer, B.K., and Urbaez Perez, E.