Over the past decade, many owner agencies across North America have recognized that the Superpave mix design system has virtually eliminated rutting in asphalt pavements.

So, why is there a need for a different approach? Agencies have indicated that distresses such as premature fatigue cracking and raveling have become the primary factor controlling the service lives of their asphalt pavements.

There are a variety of possible contributing factors to asphalt pavements cracking prematurely, including the physical and chemical properties of the asphalt cement, not properly addressing underlying pavement distresses, problems with construction quality and issues with mix designs. There is also an awareness within the industry that the Superpave mix design system generally resulted in a reduction in asphalt binder contents in many traditional asphalt mixes. That leads to the production of lean mixes that can be more prone to premature cracking and raveling.

Consequently, many agencies across Canada and the United States have started to either explore or adopt modifications aimed at refining the traditional Superpave mix design procedure to improve performance, especially the cracking resistance of asphalt mixtures. Most of the modifications are intended to increase the optimum asphalt content in the asphalt mix.

The Ministry of Transportation Ontario (MTO) recently shared their success in using the Asphalt Mix Regression Mix Design Method for increasing asphalt content in mixes.

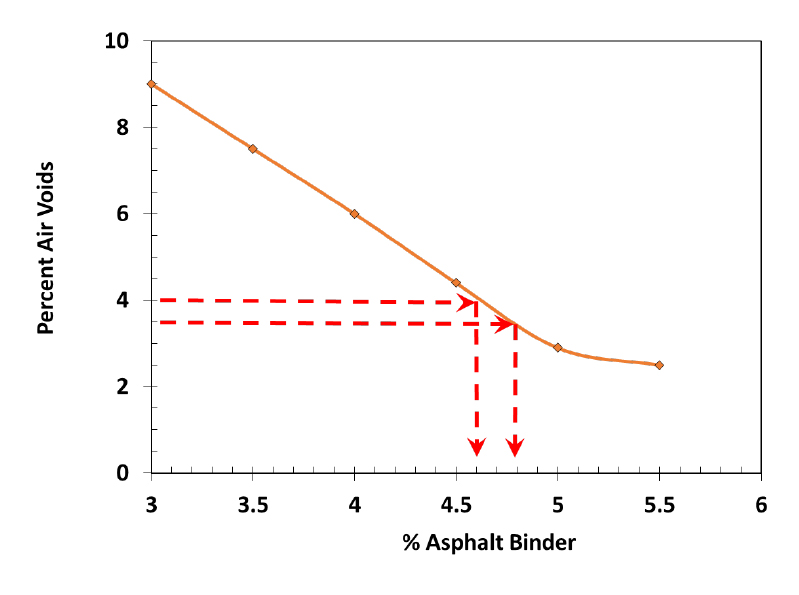

Figure 1: Example of An Air Voids vs. Asphalt Binder content plot demonstrating the use of Regression Mix Design Method: At 4.0% Air Voids, % Asphalt Binder = 4.6%; At 3.5% Air Voids % Asphalt Binder = 4.8% for production.

What is the asphalt mix regression mix design method?

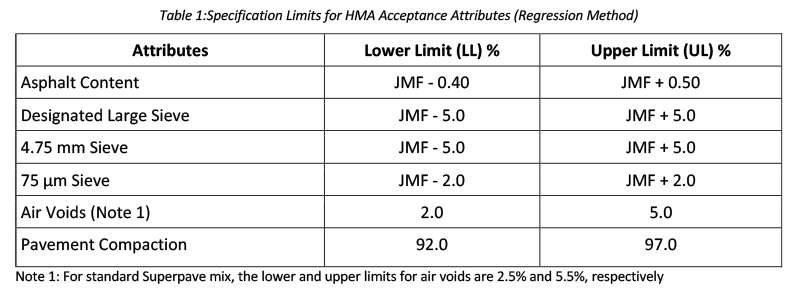

In this mix design method, asphalt binder content is selected at 4.0 percent air voids as in the traditional Superpave mix design system, then in production, the asphalt binder content is increased to an amount that will correspond to a “regressed” 3.5 percent air voids. The asphalt binder content is selected from the air voids versus asphalt binder content plot in the submitted mix design as illustrated in Figure 1.

MTO learned of this method in April 2018 during a “Partners in Quality Road Tour” presentation on “Increasing AC in Hot Mix Asphalt” given by Mr. Tom Dziedziejko, who is the Director of Quality at Aecon Infrastructure. MTO later learned that other agencies were using this method with different variations including Michigan, Iowa, Louisiana, Virginia, Colorado and British Columbia. Some agencies such as Michigan specified a regressed air void level of 3.0 percent. Other agencies such as British Columbia fixed the amount of increase in the asphalt binder content during production at 0.3 percent.

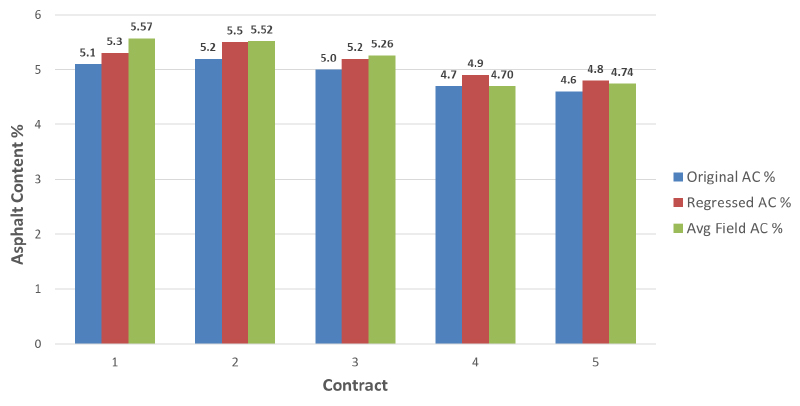

In 2019, MTO used the regression method on five paving projects across Ontario. The mix design and field production data collected by MTO showed the regressed asphalt content was between 0.2 percent to 0.3 percent higher than the original optimum asphalt in the mix design. However, some production asphalt contents increased up to 0.47 percent (Figure 2).

Figure 2: End Result Specification (ERS) highlights of mix design optimum asphalt content (original), regressed asphalt content to 3.5% air voids, and actual field results (Average ERS AC%) (Courtesy of MTO)

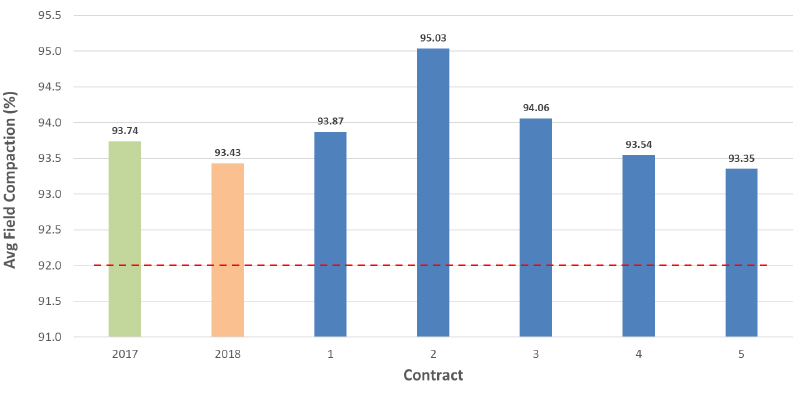

A key observation made during paving was that it was easier to achieve compaction due to better workability of the mix from the additional asphalt. In fact, the compaction results from the five paving projects showed higher average compaction levels on all five 2019 contracts using the regression method, compared to average compaction levels achieved on projects from the past two years using Superpave mix design method (Figure 3).

Figure 3: Average field compaction results from five contracts in 2019 using the regression method compared to average compaction levels from the previous two years. (Courtesy of MTO)

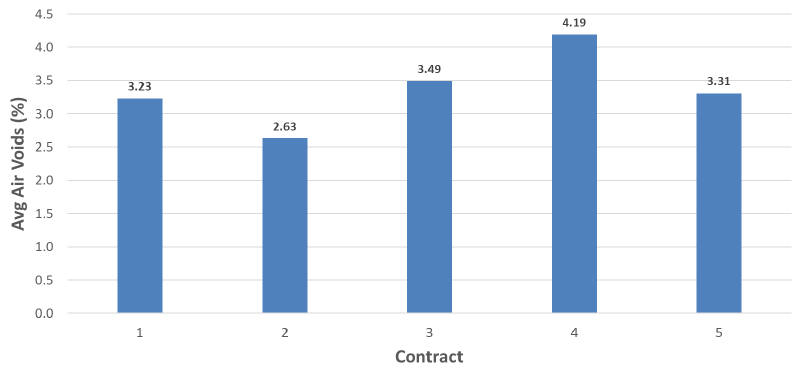

In all five paving projects, the air voids in the field met the specifications with the higher asphalt content levels (Figure 4). MTO considers these first paving jobs with the regression specification to be a success. There were no rejectable sublots due to low air voids, and there were no issues with bleeding or flushing as a result of the higher asphalt content in the mix.

Figure 4: Average air voids of production mixes from five contracts in 2019 using the regression method. (Courtesy of MTO)

MTO has long recognized the benefits of increased asphalt binder contents and has been innovative in its tendering and specifying practices in achieving this goal. Their tenders call for fixed asphalt cement values for each mix type at the time of bidding. The price of the asphalt mix is then adjusted based on the actual asphalt cement content used as determined by the acceptance testing results. With the addition of the Regression Mix Design Method, MTO expects to see an increase in service life due to the increased durability and better compaction of the mixes. They have planned at least three jobs for 2020 paving using the regression mix design method.

Seyed Tabib is the Senior Bituminous Engineer at the Materials Engineering and Research Office of MTO.

Wakefield is an Asphalt Institute Regional Engineer based in Ontario, Canada.