Gaps, challenges and the path forward

Asphalt mixtures with recycled materials, such as reclaimed asphalt pavement (RAP) and recycled asphalt shingles (RAS), have been used for decades, with some designs now exceeding 30% recycled content. However, at higher levels, these materials can stiffen and embrittle the pavement, increasing the chance of poor workability risk and premature aging, leading to an increased risk of cracking. This can compromise durability if not properly designed.

Recycling agents (RAs), first introduced in the 1970s and 1980s, offer environmental, economic, and engineering benefits for improving mixtures with high content of recycled materials. While promising, understanding their ability to restore binder properties and their long-term performance is critical. Developing robust guidelines and performance metrics will be key to ensuring their effective and widespread use in asphalt pavements. To address these needs, several national and agency-specific initiatives have been completed and others are underway. Notable efforts include National Cooperative Highway Research Program (NCHRP) projects 09-46, 09-58, and 09-65, which focus on studying the impacts of RAs and establishing performance-based metrics.

Defining the role of recycling agents

RAs are additives designed to either “rejuvenate” or “soften” the aged asphalt binder in RAP and RAS materials. RAs restore the rheological properties of aged binders through several mechanisms: (1) improving the asphaltene-to-maltene ratio, (2) reducing asphaltene cluster size, (3) enhancing the dispersive power of the maltene phase, and (4) increasing molecular mobility.

When applied at the correct dosage, RAs provide key benefits, including improved workability by reducing stiffness, enhanced resistance to cracking by mitigating embrittlement and reduction in production costs, emissions and landfill waste as they enable greater use of recycled materials. It is important to understand that these benefits rely on the RAs effectiveness and long-term impact, which depends on the binder’s origin and the specific RA used.

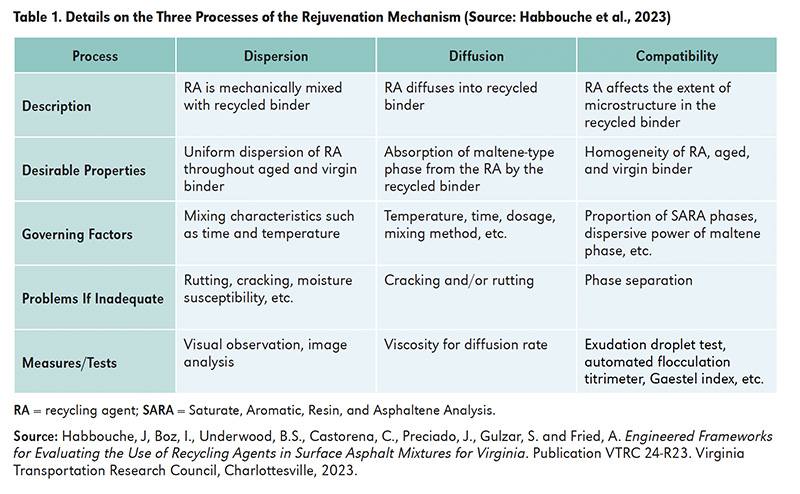

It is important to note that RAs do not reverse the chemical oxidation of an aged binder. Instead, they counteract the effect of oxidation on the binder’s rheology and performance. This rejuvenation occurs through three processes: dispersion, diffusion, and compatibility, which are summarized in Table 1.

There seems to be confusion around the terminology and classifications of RAs, with some mistakenly believing that all RAs rejuvenate the aged binder, when in fact, some RAs only act as softeners. A key chemical property influencing the performance of RAs is the saturates content. According to ASTM D4552, when the saturates percentage exceeds 30, the additive is no longer classified as a “true rejuvenator.” It should be noted that ASTM D4552 defines an RA as a “true rejuvenator,” which is reflected in the limit on saturates percentage. However, this article broadens the definition of RA to include both “true rejuvenators” and “softeners.” Previous research efforts used Atomic Force Microscopy (AFM) testing to illustrate the impact of saturates doping, highlighting the potential harm of excessive saturates in RAs. In fact, high saturates content accelerates the formation of aging-related structures within the asphalt, effectively speeding up the aging process and counteracting the intended benefits of rejuvenation. For RAs in general and rejuvenators in particular, physical properties beyond flash point and viscosity offer limited practical information. However, a more insightful approach involves evaluating the physical properties of the asphalt binder and mixtures after blending with the RA.

Rejuvenators: materials added to aged asphalt binders or RAP/RAS to restore its original properties by replenishing lost maltenes, improving flexibility, and enhancing the binder’s ability to resist cracking.

Softeners: materials used to reduce the stiffness of an asphalt binder, typically by lowering its viscosity. They primarily focus on improving workability and reducing brittleness rather than restoring chemical balance.

Evolving classification systems for recycling agents

With the increased use of RAs in asphalt mixtures, multiple classification systems have emerged, each emphasizing different criteria.

The National Center for Asphalt Technology (NCAT) classification system is a cornerstone, categorizing RAs by chemical origin into petroleum-based, organic/non-petroleum-based, and emulsion-based, with subcategories for each. While this system provides a framework, it does not fully address how RAs rejuvenate aged binders. Recent NCAT research has refined this approach, focusing more on bio-based RAs, as studies suggest they outperform petroleum-based options.

Nebraska’s research builds on NCAT’s framework, incorporating performance metrics like changes in binder performance grades and cracking resistance. It also includes advisory dosage levels for each RA class, offering practical insights for field use.

The ASTM D4552 standard, initially established in 1999 for petroleum-based RAs, was updated in 2020 to include non-petroleum options. This system evaluates physical properties like viscosity and flash point, serving as a safety and durability screening tool for asphalt plant use. Bio-based RAs generally require lower dosages to achieve similar viscosity effects as petroleum-based alternatives, although exceptions exist. In addition, as mentioned previously, according to ASTM D4552, when the saturates percentage exceeds 30, the additive is no longer classified as a “true rejuvenator.”

The Texas A&M University system, the latest innovation, categorizes RAs by rejuvenation mechanism: softeners, replenishers, and emulsifiers. This system emphasizes chemical compatibility and binder performance, recognizing differences in aging sensitivity and rheological impacts among RA types.

Each system reflects advancements in understanding RA behavior, with efforts like NCHRP Project 09-58 underscoring the need for robust specifications to rank and optimize RA effectiveness.

Replenishers: materials specifically designed to restore the chemical balance of aged asphalt binders by replacing lost maltenes and essential oils. It rejuvenates the binder, improving flexibility and durability to resist cracking.

Emulsifiers: chemical agents used to stabilize asphalt emulsions by reducing surface tension between asphalt and water.

A review of key findings from state DOTs

In 2021, during my time at Virginia DOT’s research division (VTRC), I conducted a comprehensive survey of state DOTs, RA suppliers, and binder suppliers, alongside a review of RA-related specifications and field projects, to capture the state of RA use in asphalt mixtures.

The survey achieved a 68% response rate, with inputs from 34 state DOTs. The survey covered permissibility, quality assurance (QA) practices, environmental considerations, lessons learned, and ongoing research.

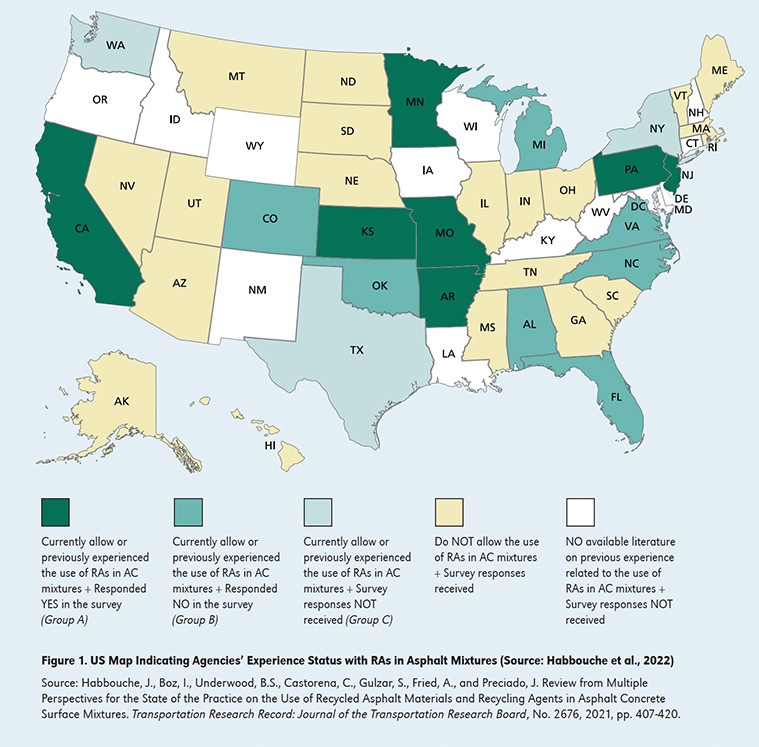

In total, 17 agencies reported using RAs in projects (as shown in Figure 1), reflecting a fourfold increase compared to NCHRP Project 09-58, where only four agencies reported RA experience in 2014. This growth underscores expanding interest and experimentation with RAs in state-level practices.

Of the respondents:

• Group A (7 agencies): Arkansas, California, Kansas, Minnesota, Missouri, New Jersey, and Pennsylvania reported RA usage. One agency restricted RA use to only mixtures with high RAP/RAS content.

• Group B (7 agencies): Alabama, Colorado, Florida, Michigan, North Carolina, Oklahoma, and Virginia had field trials or pilot projects but did not allow RAs in specifications.

• Group C (3 agencies): New York, Texas, and Washington conducted RA-related projects but did not respond to the survey.

The survey responses indicated that the primary barriers to adopting RAs included a lack of performance tests and dosage criteria (22%), limited agency experience (21%), absence of mix design methods (20%), and insufficient contractor expertise (16%). Other challenges reported included skepticism about RA effectiveness (15%), specification limits (6%), cost (3%), industry reluctance to change (3%), project selection issues (2%), and concerns over premature pavement distress (2%).

Some agencies highlighted alternative practices. For instance, Florida often uses softer binders instead of RAs to avoid jeopardizing the rutting resistance of mixtures produced with high RAP content. Georgia relies on corrected optimum asphalt content for recycled mixtures, citing better results than RA usage. Illinois noted concerns about the long-term performance of RA-modified mixtures, with reports of stiffness increases over time. Pennsylvania was researching RA testing for short- and long-term effectiveness, while South Carolina cited challenges in achieving consistent RA dosage due to RAP/RAS variability. Nebraska expressed optimism about its RA research and plans to add RAs to its approved product list (APL). Virginia was developing testing frameworks and guidelines to incorporate RAs into its APL through ongoing research.

Agencies were asked how they select and characterize RAs by type, brand, and dosage for asphalt mixtures. Most responses indicated reliance on contractors and RA suppliers to make these decisions. No agency reported implementing specific safety, health, or environmental restrictions for RA use.

Few agencies had lessons learned or best practices due to limited RA usage. Key takeaways included the critical need for project-specific dosage determination. For instance, Nebraska reported significant rutting in a test section after using an RA as a warm mix additive, likely due to excessive dosage.

Findings from NCHRP Project 09-58 and limited industry interest suggest that high RA dosage levels, combined with low permissible RAP contents, have hampered wider adoption. To ensure successful RA application, developing a robust, performance-based testing framework is essential.

Insights from RA suppliers

A survey of numerous RA suppliers revealed a mix of practices for characterizing their products. Few suppliers rely solely on standard methods like ASTM D8125-18, ASTM D4552-20, and SARA (Saturates, Aromatic, Resin, and Asphaltene) analysis for quality control. Others combine standard tests with specialized company procedures, including viscosity-aging index, gel permeation chromatography (GPC), and Fourier transform infrared spectroscopy (FTIR). Many focus on evaluating the blended binder’s performance—combining RA, virgin binder, and RAP/RAS binder—using protocols like AASHTO M 320, master curve testing, and long-term aging assessments.

For determining dosage, suppliers highlighted the importance of meeting performance targets, often using database models and cracking tests. While some suppliers provide standard dosage rates based on RAP and RAS contents, others rely on third-party labs to optimize blending rates. Terminal blending was identified as the most consistent field protocol, ensuring precise QA and certification for shipped blends.

Suppliers unanimously supported adding RAs to APLs for better control and consistent performance evaluation. Recommendations included creating a framework based on safety, proven field performance, and long-term binder and mixture testing. This approach would help differentiate true rejuvenation from temporary softening and align with performance-based mix design.

Shelf life varied, with most RAs stable for 1–2 years under proper storage. Some suppliers stressed that virgin binder quality directly affects RA stability, emphasizing the need for long-term binder and mix performance evaluations to establish effective blending thresholds and dosage optimization.

Insights from asphalt binder suppliers

Asphalt binder suppliers reported using tests like SARA analysis for new refineries and regular FTIR testing to chemically characterize binders. While crude oil sources minimally affect the performance grade (PG) of unmodified binders, they significantly influence the formulation of polymer-modified binders and emulsions, potentially impacting RA effectiveness and dosage optimization. Suppliers emphasized terminal blending of RAs with asphalt binders to ensure proper QA measures and reliable testing, allowing for consistent blending and monitoring at asphalt plants.

Bridging six knowledge gaps

The use of RAs has gained attention as a tool to enhance the use of recycled materials (RAP and RAS) while maintaining pavement performance. Despite growing interest and an increase in research, significant knowledge gaps remain. Recent advances have proposed new methods for understanding RA interactions and achieving acceptable performance through dosage selection, but critical challenges persist:

• Classification systems: A universal, source-independent classification system for Ras remains absent. At one end of the spectrum, current approaches, such as the Texas A&M system – the most advanced method to date – still oversimplify the complex interactions between virgin binder, RAP binder and RAs. At the other end, standards like ASTM D4552 lack sufficient integration of physical property assessments when RAs are blended into binders and mixtures. To address these gaps, a more comprehensive system that incorporates chemical, rheological, and microstructural evaluations is needed for improved RA screening and selection.

• Dosage selection methods: Existing methods focus on individual properties, but a unified approach ensuring optimal performance across all temperatures and conditions has yet to be developed.

• Meta-analysis of research: Considerable research has been dedicated to understanding the impact of RAs on the performance of recycled asphalt binder blends and mixtures. These studies have varied multiple factors, including mixing conditions, testing environments, and the incorporation of additional additives. However, many of these studies have not significantly advanced the collective understanding of RA effectiveness since the foundational work in NCHRP Project 09-58. A meta-analysis of existing research is needed to identify key factors that influence the successful use of RAs in asphalt mixtures and provide clearer guidance for future applications.

• Modeling RA impacts: Limited efforts have been made to model the effects of RAs on recycled binder blends and mixtures. Further research is crucial to understanding their rheological and performance impacts as well as their long-term effectiveness.

• Cost considerations: The cost of RAs varies based on type and dosage, which can be of prime importance. Few studies have addressed methodologies that incorporate cost-effectiveness into RA selection.

• Environmental Impact: Since most RAs are chemically active, the environmental effects of their use remain largely unexplored. This includes potential emissions during asphalt mixture production and long-term environmental impacts. More research is needed to fully understand how RAs influence both immediate environmental concerns, such as air quality during production, and their lasting effects on ecosystems once the pavement is in service.

Overall, the lack of standardized metrics for evaluating RA effectiveness complicates adoption. Contractors often propose dosages, leaving DOTs to determine their suitability. Moving forward, robust frameworks for screening, evaluating, and applying RAs in recycled asphalt mixtures –tailored to local practices – are critical to maximizing their potential.

Closing remarks and future efforts

The topic of RAs in asphalt mixtures is broad, encompassing history, composition, laboratory research, field trials, current practices, sustainability, and more. Significant efforts have been made to address various aspects of RAs, including NCHRP Project 09-58, VTRC’s 2021 work, and NCHRP Synthesis 586 published in 2022, which documented current State DOT practices for using RAs in asphalt mixtures with recycled materials. Many other laboratory and field-related efforts have also been documented in the literature. However, these studies provide limited field performance data and may overlook practices from states with different raw materials or climates.

Since these reports, numerous additional efforts have aimed to address these gaps. One such initiative is a cooperative agreement between the Federal Highway Administration (FHWA) and the University of Nevada, Reno (UNR), supported by institutions including the Asphalt Institute (AI), NCAT, VTRC, Asphalt Testing Solutions & Engineering (ATSE), and National Asphalt Pavement Association (NAPA) through the AIEI program (Asphalt | Innovate | Enlighten | Implement). As part of this program, a statement of work has been developed to document the practices of selected State DOTs using RAs in asphalt mixtures. This effort is being led by me, alongside Dr. R. Grover Allen, Asphalt Institute’s Southeastern Regional Engineer and research scientists from VTRC at Virginia DOT.

Through interviews with personnel from these DOTs, we are capturing lessons learned, challenges and best practices. The goal is to establish a comprehensive understanding of how different agencies are implementing RAs, providing valuable examples for other states considering this approach.

I look forward to sharing further updates on this research and exploring these topics in greater depth in future articles on the use of RAs in asphalt mixtures.

Habbouche is an Asphalt Institute Regional Engineer based in Arizona.