Three steps to properly calculate batch weights for asphalt specimens using RAP

We see it every day in the industry: asphalt mixtures with 25% RAP, 15% RAP, etc. But if I see 23% RAP on a mix design, what exactly is it a percentage of? Many people would say either that it’s a percentage by weight of the total aggregate or of the total mix. Neither is correct. It can’t be a percentage of the total aggregate weight, because RAP also includes the weight of the RAP binder. It can’t be a percentage of the total mix weight, because the percentages listed at the top of a mix design that add up to 100% don’t include the additional virgin binder in the mix.

Whenever percentages of materials in an asphalt mixture are designated, we must ask the question, “this is a percentage of what?” Some frequently discussed percentages like air voids and VMA are a percentage by volume of the total mix volume. Others, such as binder content, are expressed as a percentage by weight of the total mix weight. RAP is different, though, as the percentage of binder in the RAP is expressed as a percentage of the total RAP weight. Before adding, subtracting, multiplying, or dividing any percentages, they must be converted so that they are all a percentage of the same thing. That’s why we can’t add, for example, 4.0% air voids (Pa) and 5.0% effective binder (Pbe) and say the VMA must be an extremely low 9.0%. We first have to convert Pbe to a percentage of the total mix volume (e.g. 11.6%). Then the two VMA components can be added, resulting in a much more reasonable %VMA (4.0 + 11.6 = 15.6). Asphalt Institute’s “MS-2, Asphalt Mix Design Methods”, uses the following terms:

• RAPbinder – the part of the RAP material that is binder

• RAPaggregate – the part of the RAP material that is aggregate

• RAPcoldfeed – the material in the RAP cold feed bin, which includes both RAPbinder and RAPaggregate

Going back to the first question in this article, if I say “23% RAP,” what I mean is that of all the materials being batched from the asphalt plant’s cold feed bins (including the RAP bin), 23% of it by weight is RAP. That number is different than the RAP calculated as a percentage of the total aggregate weight or the total mix weight.

When the percentage of RAP used in a mix is lower – a situation common in the past – then the error introduced by using an incorrect percentage in the calculations is relatively small. At around 20% RAP, errors tended to show up as 1-2% differences in the percentages passing a couple of sieves and about 1% lower RAP content than what most practitioners thought they were using. As the percentage of RAP in asphalt mixtures increases, the errors introduced by using an incorrect percentage will also increase.

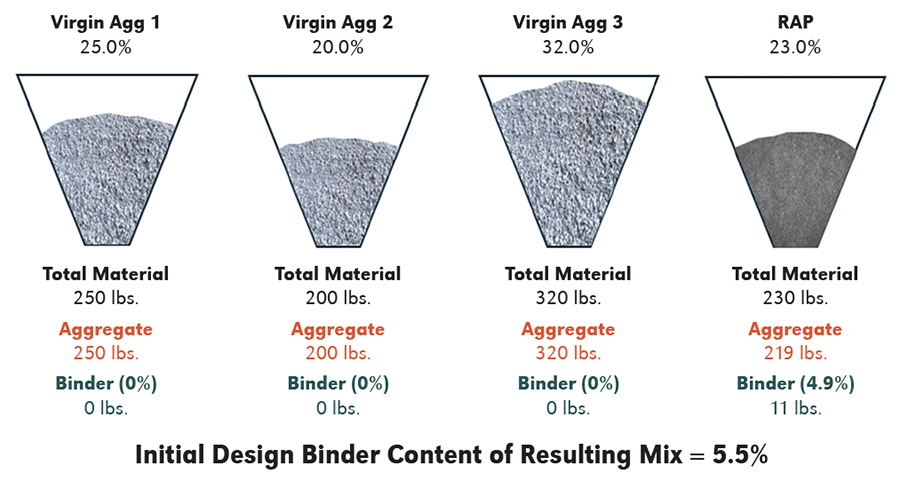

Nothing seems to clarify a point like an example, so let’s assume some numbers for an example mix design and carry them through. It may also make it easier to visualize the percentages if we say that at a particular moment in time, the cold feed bins and RAP bin have discharged a total of 1000 lbs. of material onto the conveyors. In three easy steps, we’ll calculate the weight of each component for batching an asphalt mix design containing RAP.

How did we arrive at the total material weight on the conveyors from each cold feed bin for this example?

We just multiplied the percentage from each bin by the total weight of 1,000 lbs.:

1000 lbs. x 25% = 250 lbs. Virgin Aggregate 1

1000 lbs. x 20% = 200 lbs. Virgin Aggregate 2

1000 lbs. x 32% = 320 lbs. Virgin Aggregate 3

1000 lbs. x 23% = 230 lbs. RAP

1000 lbs. of material from the cold feed bins

STEP 1:

How much of the RAPcoldfeed is RAPaggregate and how much is RAPbinder?

The RAPaggregate percentage from the cold feed bin is always lower than the percentage of the RAPcoldfeed.

In this example, we said that the %RAPcoldfeed is 23 and Pb, RAP is 4.9.

Therefore, out of the 230 lbs. of RAP from the cold feed bin in this example, (21.9% x 1000 lbs.) 219 lbs. is RAPaggregate. Subtract the weight of the RAP aggregate from the total RAP weight to get the RAPbinder weight of 11 lbs.

STEP 2:

What is the percentage of each aggregate used by weight of the total aggregate?

First, we add up the total aggregate weight on the conveyors from the bins, remembering to only include the aggregate portion of the RAP weight.

250 lbs. Virgin Aggregate 1

200 lbs. Virgin Aggregate 2

320 lbs. Virgin Aggregate 3

219 lbs. RAP Aggregate

989 lbs. of aggregate from the cold feed bins

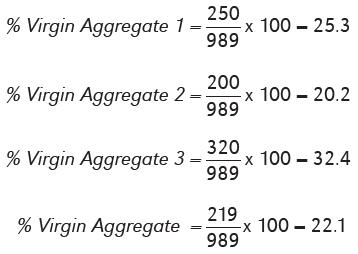

To get the percentage by weight of the total aggregate, we can divide each aggregate weight by the total aggregate weight and convert the resulting decimal to a percentage:

As a check, make sure that the aggregate percentages total 100:

25.3% + 20.2% + 32.4% + 22.1% = 100%

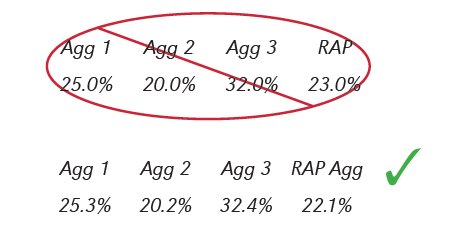

When calculating the combined gradation for each sieve or the aggregate batching proportions, make sure to use only these calculated aggregate percentages, not the cold feed bin percentages.

STEP 3:

How many grams of each material (virgin aggregate, RAP, and virgin binder) do I batch for a given total aggregate batch weight?

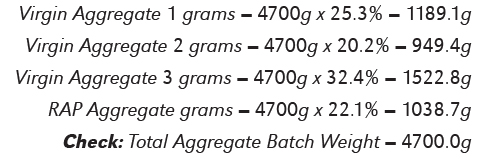

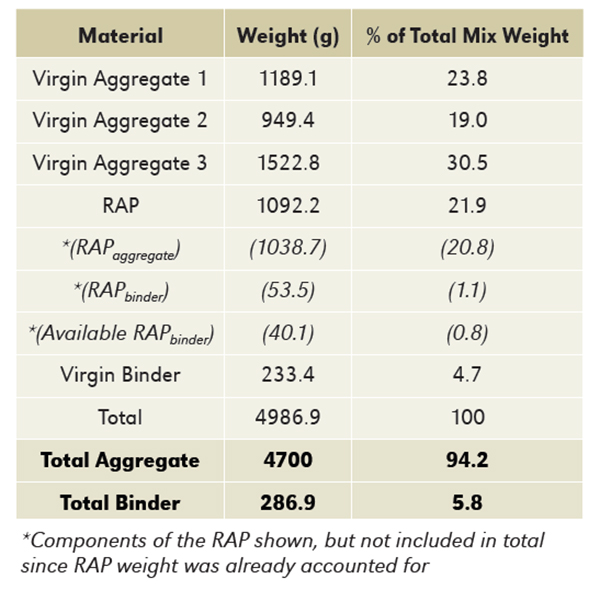

Decide how many grams of total aggregate you want to batch using the component materials. In this example, we’ll batch 4700 grams of total aggregate, properly proportioned.

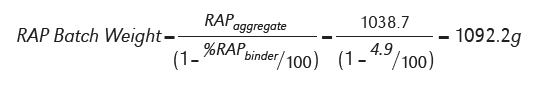

When batching RAP designs, we batch the total RAP, not just the RAPaggregate, so we need to calculate how many grams of RAP will contain the right amount of RAPaggregate. For this example, 1038.7g of RAPaggregate using RAP that contains 4.9% binder will need what RAP batch weight?

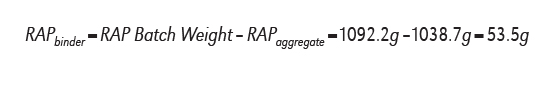

Since we now know the weight of the RAP and the weight of the RAPaggregate, it is easy to calculate the weight of the RAPbinder:

Batching considerations with RBA

One question that needs to be asked at this point is how much of the RAP binder is actually active and available for blending with the virgin binder? The most common—but almost certainly incorrect—approach to designing RAP mixes is to assume that 100% of the RAP binder is available. To address this issue, several states have adopted a Recycled Binder Availability (RBA) factor. RBA recognizes that the binder in the RAP is significantly stiffer than the new binder being added, and as a result not all of it is activated or blended with the new binder. While there is some uncertainty in that the true RBA varies from one RAP stockpile to the next, one thing that is certain is that the binder availability is less than 100% regardless. In this example, we’ll assume for design purposes an average RAP binder availability of 75%.

Available RAP Binder = 0.75 x 53.5 = 40.1g

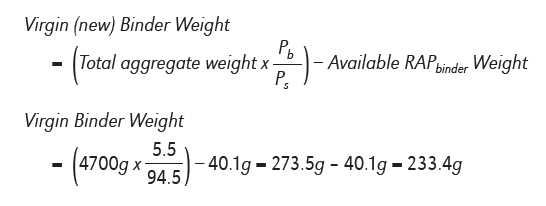

The last component to calculate in step 3 is the virgin binder weight. Designers should already know how to calculate the total design binder content. When we determine the virgin binder weight, we simply calculate the initial design binder content and subtract the available RAP binder portion.

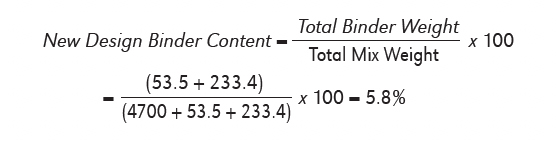

Note that adding the extra virgin binder to account for the RBA factor increases the design binder content to 5.8% (although only 5.5% is active).

In the mixing bowl or bucket, we add:

In this example:

As a percentage of the total cold feed material, % RAP= 23.0

As a percentage of the total mix weight, % RAP= 21.9

As a percentage of the total aggregate weight, % RAP = 23.3 (100 x 230/989)

As technical people, it is unacceptable to rationalize that a difference of around 1% is not much when we can just as easily calculate the correct number. As RAP percentages increase, the difference also increases. In a world where specific gravities are calculated to three decimal places, we should be careful to use the proper percentage when doing RAP calculations.

In summary, it’s essential to know what “% RAP” refers to. In mix designs, “% RAP” means the weight of RAP expressed as a percentage of the total cold feed material weight. A single number cannot represent multiple different properties. If we express “% RAP” as a percentage of something else, we must clearly identify what it’s a percentage of and calculate each percentage separately.

Gierhart is the Asphalt Institute Director of Engineering and Training.