Since the late 1990s, pavement durability and cracking have become the primary asphalt pavement distress. Before the Strategic Highway Research Program (SHRP), rutting was the primary distress. Improvements in aggregate quality, mix design and polymer binders have almost eliminated the problems with rutting. Now is the time to investigate cracking.

The amount of research on cracking in pavements has increased tremendously over the past several years. The National Cooperative Research Program (NCHRP) performed numerous projects looking at both binder and mix, geared at looking at measuring cracking properties. One problem is that cracking is a much more complicated issue than rutting.

As noted earlier, stiffer binders and better aggregate structures have eliminated most of the rutting problems. With cracking we have multiple types of issues. Is it top-down, bottom-up, longitudinal, transverse or block cracking? Each type of cracking has a different cause and can have several fixes. Asphalt binders change with age, they become stiffer and more brittle. This makes cracking more dependent on the aged condition of the binder. Rutting is an early-life distress because the binder is the softest when the asphalt mixture is first constructed and stiffens with age. In this case, the aging helps mitigate the problem. With cracking the binder properties change as a result of aging and they become more prone to cracking. Another cause of cracking is related to the amount of binder that is in the mix. Using more binder usually reduces cracking, but it will increase cost and may take us back to rutting problems.

A lot of the research over the past few years has been performed to identify what properties of the binder best relate to cracking. We have always known some binders have less of a problem with cracking than others, but how to measure it? Many of the early tests, such as pen and ductility, only looked at the softness of the binder. For cracking, it was considered softer was better. Unfortunately, these tests where not run on aged material though, when cracking usually occurs. Also, there was never a good correlation between roadway cracking and pen and ductility.

The Superpave binder specifications were supposed to address cracking issues. The Bending Beam Rheometer (BBR) seems to be doing a good job of addressing low-temperature transverse cracking, but that is not the distress showing up on the pavements today. The Superpave intermediate DSR property, G*sinδ, was intended to address durability but it hasn’t worked. The current intermediate DSR requirement has only been poorly related to durability cracking. This is why an extensive study is underway to try and replace it.

Over the years several different parameters have been proposed as a replacement for the current intermediate temperature DSR requirement. All of those parameters were developed from rheological data using the same testing equipment we have now but only testing at different temperatures and analyzing the data differently.

In 2011, the Asphalt Institute (AI) as part of an FAA study on durability and cracking on airfield pavements evaluated ΔTc as a measure of cracking. This is a value determined from the bending beam rheometer S and m measurements at two temperatures. The specific temperature where the stiffness (S) meets 300MPa and the m value meets 0.3 are determined. These temperatures are almost never the same. This is where the delta (Δ) comes from. The Tcritical for m is subtracted from the Tcritical for S and ΔTc is determined. A value for Tc,S of -26.2 minus a value of Tc,m of -25.9 gives a value of -0.3 ΔTc. The field study indicated the larger and more negative the difference the more prone the pavement is to cracking.

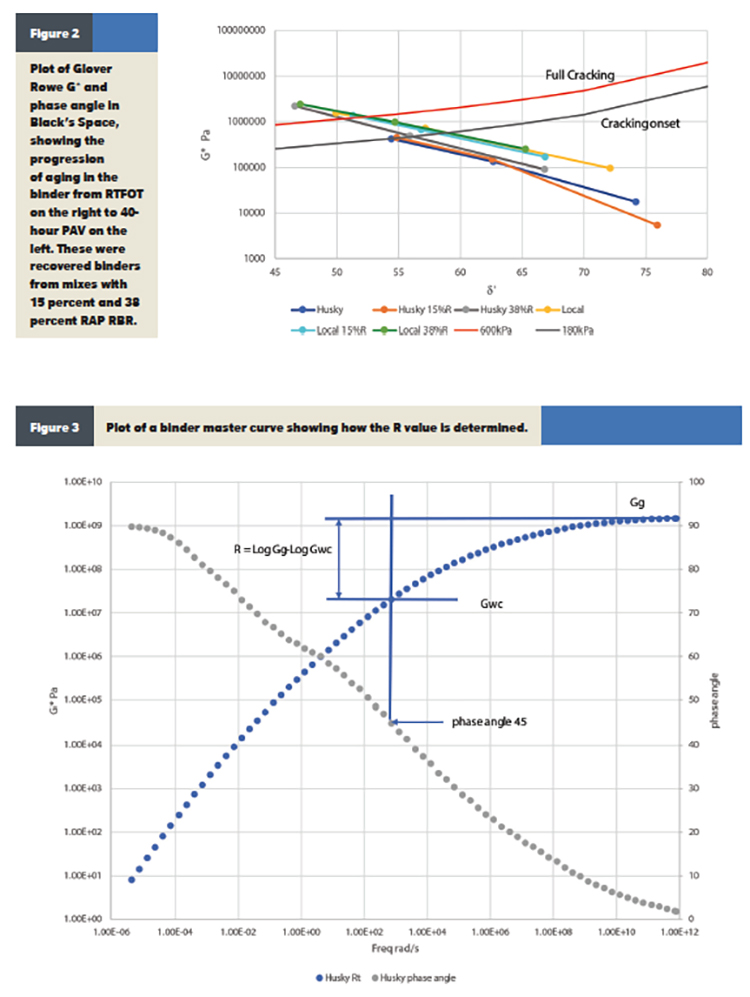

As part of the same AI study, an estimate of ductility determined from DSR testing was also compared to ΔTc. This ductility estimation was developed by Charles Glover of Texas A&M. The ductility work was based on the idea that when the ductility of the asphalt is at 5cm at 15°C there is the onset of cracking in the pavement. Geoff Rowe later provided a simplified equation for the ductility estimate from DSR data in a new parameter called the Glover-Rowe value, G*x (cosδ)2/sinδ. To calculate the Glover-Rowe parameter, complex shear modulus (G*) and phase angle (delta) are measured at 15°C and a frequency of 0.005 radians/second in the DSR. The Glover-Rowe parameter is also being evaluated as a cracking indicator by several researchers. Some researchers like the Glover-Rowe parameter because it can be plotted easily as shown in Figure 2. The Glover-Rowe parameter can also be determined for different aging conditions. In Figure 2 the lower values to the right of each binder are from RTFOT aging followed up and to the left with 20-hour and 40-hour PAV values.

Another property that has been looked at to evaluate aging of the binder is the R value or rheological index. The R value is the log of the glassy modulus of the binder minus the log of the modulus where the phase angle is 45°. The glassy modulus is the modulus where the phase angle is basically 0° or almost completely elastic at low temperature. This is shown graphically in Figure 3. The larger the R value, the more brittle and prone to cracking the aged binder is likely to be. This property typically requires more testing of the binder at multiple temperatures and frequencies.

The crossover temperature is another property related to cracking. This is the temperature at which the phase angle is 45°, identified as Twc, when tested at a specific frequency. The original work from Europe used 2.4 rad/s. In the US work from NCHRP 9-58 “The Effects of Recycling Agents on Asphalt Mixtures with High RAS and RAP Binder Ratios,” used 10 rad/s to be in line with the current test procedures used in the Superpave specifications. This value is an indicator of the temperature when the asphalt binder transitions from a viscous material to an elastic material. The lower the temperature when the material becomes elastic the less prone the binder is to cracking.

If your head is not spinning yet just wait. There are more criteria and changes coming from other projects.

NCHRP 9-59, “Relating Asphalt Binder Fatigue Properties to Asphalt Mixture Fatigue Performance,” is recommending the use of several of the listed cracking properties but modifying them so they are easier to determine and changing the temperatures to better relate them to climate.

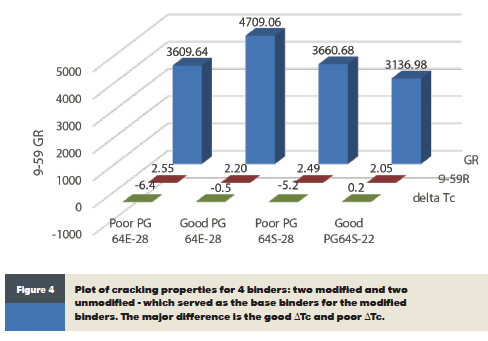

The 9-59 project recommends keeping the same calculation for the Glover-Rowe parameter GR= G*(cosδ)2/sinδ except the temperature and frequency are different. The frequency for testing is 10rad/s, instead of 0.005 rad/s, and the temperature is not the standard 15°C but is shifted to vary based on low temp grade; testing at 22°C for a -28 grade and 25°C for -22 grade. The 9-59 R is estimated using just BBR S and m at the low temperature grade and calculated as R= log(S/3000)/log(1-m). There was no recommendation for changes to the ΔTc calculation.

The 9-59 project is also making some recommendations on limits for the criteria. For the Glover-Rowe parameter they recommended a max of 5000kPa, for R value it should be between 1.5 and 2.5 and for ΔTc the recommended minimum would be -5. The problem with all these values is that they all correlate well for neat binder but for modified systems things start to get fuzzy. With modified systems the phase angle in the intermediate temperature range will typically have flat spots or areas where there is little change with temperature. This behavior can affect the response of the different parameters.

To explore the NCHRP 9-59 parameters an independent study was initiated with both modified and unmodified asphalt binders Base binders with good and poor ΔTc were used to produce polymer modified binders. The high temperature grade and low temperature grade for the neat and modified binder were held as close as possible. The data is shown in Figure 4. One of the binders, the Good PG 64S-22, looks like it has a different low temperature grade but it actually just misses the -28 criteria and is within 2 degrees of the other binders. A comparison of the different criteria is very interesting. The difference between the good and poor ΔTc is very large, basically 0 for the good binders and -5 or -6 for the poor binders. Looking at the R values the comparison gets a little cloudier. The R values don’t show a large difference. While the poor binders are at or close to the recommended high value of 2.5, the Good 64E-28 binder at 2.2 is also getting close to the limit. The concerning value is the Glover-Rowe parameter. The Good PG64E-28 with a good ΔTc value and a reasonable R value is almost over the Glover-Rowe limit of 5000 kPa, while the poor binders with bad ΔTc values and bad R values have good Glover-Rowe values. This just goes to show the complexity of trying to determine cracking criteria and setting specifications limits. Using ΔTc would indicate two of the binders are very good and two are poor. The R values convolute this some but show the same trend and the Glover-Rowe values actually reverses the recommendations.

One last complication is climate and PG grading, specifically adjusting the criteria for when softer binders are used in a warmer climate. It is very common to use a -22 grade binder in the south where the climate grade is -16 or -10. Should the criteria stay the same compared to where the binder grade used is close to the climate temperatures? How best to adjust them if they should be adjusted?

Cracking has taken over as the more predominant distress in pavements over the past few years. We know the binder properties have an effect on cracking, but how best to determine that effect still needs work. Let’s not forget the many other things that affect cracking like mix design, structural design and construction practices. Cracking is a very complex mechanism and there is not likely to be an easy fix.

D’Angelo is an asphalt consultant based in the Washington, D.C. area.