Deep milling and paving at Ronald Reagan Washington National Airport

Ronald Reagan Washington National Airport (DCA) has long served as a critical aviation hub for our nation’s capital. Since its opening in 1941, DCA has evolved into one of the busiest airports in the United States. Notably, DCA’s two runways have remained 100% asphalt since their inception — a testament to the flexibility, resilience and performance asphalt offers in high-demand aviation environments.

This article examines the 100-million-dollar rehabilitation project on DCA’s two runways, RW 1-19 and RW 15-33 constructed in 2023 and 2024. This ambitious effort involved deep milling and repaving during nightly runway closures while ensuring the runways returned to service each morning. The project tackled complex challenges such as intersection closures, material logistics and strict time constraints.

A brief history of DCA

DCA’s story begins just before U.S. entry into World War II, when it was built on mudflats along the Potomac River. Over its eight decades of service, DCA solidified its status as a key aviation facility in the mid-Atlantic region. In the 1980s and 1990s, major paving works expanded and strengthened both runways while consistently preserving asphalt as their surface. By the early 2000s, DCA managed an ever-growing passenger base and flight load, reinforcing the significance of maintaining good pavement conditions to ensure safe and efficient operations.

Primary RW 1-19 is 7,169 ft long by 150 ft wide and receives 94% of all DCA operations or 819 flights per day. Secondary RW 15-33 is 5,204 ft long by 150 ft wide and receives 6% of DCA’s flight operations.

Project background and objective

The last major improvement to DCA’s runways was completed in 2010 and 2011, a 3-inch mill and overlay. Continuous traffic from increasingly larger aircraft continued taking its toll on both runway surfaces with increased distress and deterioration.

A 2019 pavement management study confirmed what engineers had already suspected: deeper repairs and complete rehabilitation were necessary. Core samples, ground-penetrating radar (GPR), and heavy-weight deflectometer (HWD) testing indicated structural issues, including delamination at various depths and layers below the surface lift where stripping was occurring, leaving disintegrated asphalt mix with low binder content. Stripping is an asphalt mix phenomenon where the asphalt binder strips away from the aggregate surface, resulting in a poorly bound, or unbounded, layer. The good news is that the CBR values of the subgrade still indicated strong support.

The Metropolitan Washington Airport Authority (MWAA), working with Crawford, Murphy & Tilly (CMT) and RDM International (RDM), launched an ambitious rehabilitation program for both RWs 1-19 and 15-33, and associated taxiways. The project team’s goals were clear:

• Deliver long-term durability – beyond routine surface mill and overlays.

• Maintain safe and smooth pavements – for aircraft takeoffs and landings.

• Minimize impact on airport operations – allowing scheduled flights to resume each morning.

• Design strength must support future aircraft – including larger jets and higher daily operations.

Pavement evaluation and design approach

A cornerstone of this rehabilitation effort was the methodical pavement evaluation. Following up on the 2019 pavement management study, CMT and RDM engineers conducted a much more extensive pavement evaluation that included:

Detailed Visual Inspections – Cataloging surface distresses like cracking, rutting, raveling, and any foreign object debris hazards.

Heavy Weight Deflectometer (HWD) Testing – allowed engineers to measure pavement deflection under loads, giving insights into layer stiffness.

Ground-Penetrating Radar (GPR) – A mapping tool to identify variable asphalt thicknesses and detect anomalies within the pavement.

Core Extraction – Over a hundred cores taken from both runways helped confirm the depth and extent of deterioration, revealing stripping down to 8 inches in depth.

Rich Thuma, Senior Project Engineer for CMT, stated, “Our comprehensive pavement evaluation revealed widespread stripping and deterioration that required more than a simple overlay.

Mark Puttock, Design Project Manager for MWAA added, “Deep milling became the best solution to give DCA a long-lasting runway pavement, ensuring safety for decades to come.”

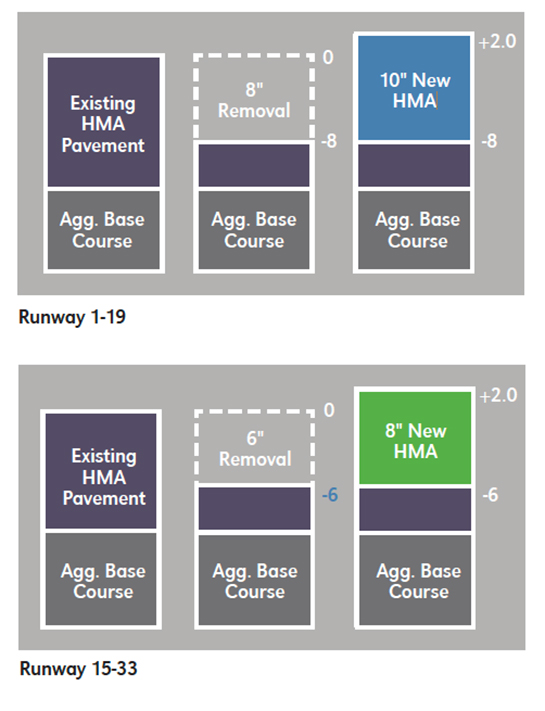

The final design called for an 8-inch asphalt removal (sometimes 6-inch on Runway 15-33, depending on depth of deterioration) and a multi-lift replacement with high-performance asphalt. Overall, each runway’s total thickness was increased by two inches to accommodate heavier aircraft in the future.

Required pavement structures

Unique challenges

As part of project planning, MWAA and its design team of CMT and RDM negotiated with the commercial airlines operating at DCA for adequate closure periods to be able to conduct the necessary rehabilitation work. The outcome provided a relatively small nightly window for compressed operations, demanding innovative scheduling and construction phases over the entire project.

Nightly closure windows

• Runway 1-19 could only close from 11 p.m. to 6 a.m.- a strict seven-hour window with severe liquidated damage penalties for every minute past 6 a.m.

• Runway 15-33 featured slightly longer nighttime closures of around 10 hours.

• Intersection work, where the two runways cross, was even more restricted, often limited to 5.5 hours on all nights, except Saturday.

• These times were non-negotiable, creating a “race against the clock” for the construction teams.

Intersection constraints

The biggest scheduling puzzle was the runway intersection, where closures impacted both runways simultaneously and risked broader disruptions across DCA’s flight schedule. The team allotted the intersection work for specific periods in the summer months with fewer storms, increasing predictability. Carefully planned shorter closure windows, usually around five to six hours, proved sufficient through rigorous pre-planning and resource mobilization.

Coordinating electrical upgrades

The simultaneous need to replace runway centerline, edge, and touchdown zone lighting systems from older quartz or incandescent to LED fixtures added complexity. Crews had to integrate trenching for new conduit lines and new can installation with milling and paving, ensuring new asphalt elevations didn’t conflict with lighting component depths. Integrating this with paving operations proved one of the project’s more complex undertakings.

The design team, working with MWAA, developed a detailed eight-phase schedule which called for the project to be accomplished over the 2023 and 2024 construction seasons. The first year focused on base removal and replacement of the primary RW, part of the secondary RW, and RW intersection, before the winter shutdown. The second year completed base course removal and replacement of the secondary RW before focusing on the final surface course and grooving.

Asphalt Institute delivers clinic

MWAA hired the Asphalt Institute to conduct a two-day Airfield Paving Clinic in January of 2023 in preparation for the project. The entire project team was in attendance, including the construction contractor (Lagan U.S.), design consultants (CMT, RDM, ADCI), the quality assurance testing firm (EM Tech), and MWAA personnel. Airfield paving best practices and associated FAA standards (i.e., P-401) were covered as well as specific aspects of the project. Afterward, James Keogh, Operations Director of Lagan, expressed appreciation by writing: “We found the clinic to be informative and constructive for the upcoming project and also for future ones.”

Deep milling and paving operations

The crux of this rehabilitation was deep milling, which involved removing eight inches of existing asphalt, and then replacing it with two four-inch lifts of new FAA P-401 mix. This all had to be done in fixed 7-hour windows each night before opening the runway for aircraft operations each morning at 6 a.m. The contractor, Lagan U.S. Inc., accomplished this by typically removing and replacing 1,000-foot sections at a milling and paving width of 15 feet.

According to Donald Bloodworth, Managing Director for Lagan U.S., “A big challenge was managing the deep milling and paving in such short time windows. Precision planning and execution were paramount.”

Keogh added: “Every piece of equipment, every truck, every person had a specific task in a precise timeframe. Missing a beat could mean a delay in reopening the runway.”

Two asphalt mix plants were utilized simultaneously on this project. An on-site batch plant was assembled and operated by Lagan on DCA property. In addition, a nearby permanent plant operated by Holcim Inc. was used. The proximity of the plants allowed tight temperature control of the mixture, which was critical, especially in cooler overnight conditions where mix cooling can shorten workable compaction time. Since the area designated for the batch plant was small, aggregate stockpiles and asphalt binder were replenished daily to ensure stable production of 400 to 600 tons of asphalt mix per night.

The early phases of the project called for the milling and replacement in two lifts of an FAA P-401 base mix with a polymer-modified PG 76-22 binder. The later phases called for a ½” mill of that same base mix to remove rubber contamination, paint and grooves and then placing a single 2.5-inch lift of FAA P-401 surface mix with a polymer-modified PG 82-22 binder.

Pavement rehabilitation approach

The job mix formula of the surface mix called for a 5.3% optimum binder content and a 5.5% passing the #200 sieve. The stiffer PG 82-22 binder enhances the resistance to high tire pressures and shear stresses. This design provided the extra 2 inches of asphalt thickness for additional structural strength needed for heavier future aircraft loadings.

Aggregate gradation and binder content were carefully controlled to achieve consistent compaction and smoothness within the short production windows.

A straight PG 64-22 was used for the tack coat, as opposed to an emulsified tack product, which allowed paving to proceed without waiting for the tack to break. A uniform tack coat application was essential for bonding the new lifts, even lifts placed on top of each other the same night. The detailed design plans called for transverse and longitudinal joints to be offset between lifts, mitigating crack propagation.

Field laboratories tested mix samples for density, air voids, and gradation each night. The P-401 acceptance and pay factors had to be calculated separately between the two plants. Real-time adjustments in production prevented mix from falling out of compliance. Coordination between the asphalt plant and paving crew kept production balanced. Over the entire project, the average pay factor for 65 lots of the 82-22 surface mix was 104% while the average pay factor for 100 lots of the PG 76-22 base mix was 102%.

“Maintaining uniform compaction night after night requires excellent communication between the asphalt plant, site teams, and quality control staff. For a high-profile runway, the margin for error is narrow,” said Chris Decker of RDM.

Extensive smoothness testing was employed, including straightedge checks to verify that each night’s newly placed surface met stringent smoothness criteria. Consistent depth control and precise paver automation systems helped maintain an even surface across the transverse construction joints created each night. The final 2.5-inch surface lift was sequenced in a manner where transverse construction joints were minimized, providing for a smoother finished runway.

Construction sequencing: The nightly ‘race against the clock’

6:30 p.m.: Go/No-Go meeting

The contracting team, airport operations, and other stakeholders finalize plans. Weather forecasts and equipment status are reviewed to decide if work can proceed. The contractor’s team conducts pre-start safety meetings to confirm tasks, walk through hazard assessments, and ensure every crew member understands the critical timeline.

9:00 p.m.: Asphalt production begins

The on-site plant fires up, ensuring mix availability as soon as the runway closes.

11:00 p.m.: Runway closure

Once the last scheduled aircraft has landed, airport operations hand over the runway. Crews immediately set up barricades and “Flashing X” beacons to signal the closure to any errant traffic.

11:15 p.m.: Milling and electrical demolition

Milling machines remove the top eight inches of asphalt, while separate teams remove and/or demolish existing runway centerline and touchdown zone lights as required.

1:00 a.m.: First lift of asphalt placement

With milling finished in a portion of the runway, paving commences. Asphalt mix is placed in a four-inch lift and compacted. The second four-inch lift soon follows. Sufficient cooling of the first mat to support the paving equipment of the second lift was not an issue.

4:30 a.m.: Paving complete

Final compaction is achieved, and temperature checks confirm readiness for paint.

5:00 a.m.: Temporary pavement markings

Striping crews apply essential guidance markings. These are temporary but vital for safe aircraft movements each morning.

5:30 a.m.: Barricade removal and cleanup

Teams clear the runway of all equipment, do a final sweep for foreign object debris (FOD), and prepare for the official inspection.

6:00 a.m.: Runway reopens|

Airport operations conducts a final check. With everything in order, the runway is reopened to the first flights of the new day.

By repeating this sequence night after night and carefully coordinating each work element, the project advanced in a steady, predictable manner. Any slip in timing could have forced an extension to the closure, creating ripple effects for airline schedules.

“The level of intricate scheduling has been amazing. Every night is a race against the clock, and failure is not an option,” said Priyam Shah, MWAA Construction Manager.

Conclusion and future outlook

The deep milling and asphalt replacement at DCA required carefully orchestrated engineering and construction. By adhering to strict nighttime closure windows, the project team restored the critical runway pavement while minimizing interruption to flight operations. DCA’s upgraded runways are poised to serve the capital’s travelers well into the future.

Beyond DCA, many airports face similar constraints – a constant juggle between heavy air traffic, narrow construction windows, and pressing infrastructure needs. This project demonstrates that meticulous planning and design, comprehensive testing, innovative scheduling, and attention to detail during construction can overcome such challenges — undoubtedly informing future airport rehabilitation projects.

Buncher is the Asphalt Institute Vice President of Engineering.

By the numbers:

183,000 tons of P-401 asphalt mix

Over 500,000 square yards of milling

Over 350,000 square yards of grooving

1,300,000 square feet of pavement markings