In the last installment of Lab Corner, we discussed “asset” recovery in the lab—specifically the recovery of asphalt binder from a sample of asphalt mixture, pavement core, reclaimed asphalt pavement (RAP) or reclaimed asphalt shingles (RAS). However, recovery is not the end of the process, but rather just the beginning step needed to characterize the physical properties of the asphalt binder.

Once an asphalt binder has been recovered from a sample, the asphalt technologist needs to exercise some judgment on how to proceed. Generally, we assume a recovered asphalt binder has been subjected to at least the equivalent of aging through the Rolling Thin-Film Oven (RTFO). In reality, if the asphalt binder was recovered from mix produced in the lab or from field-produced mixture that was sampled immediately after production, then the asphalt binder might have been subjected to aging that is less than that simulated by the RTFO.

The SHRP A-003A research at Oregon State University indicated that the aging of an asphalt binder can be reduced by the interaction with the aggregates in a mixture. In other words, the RTFO may be too severe compared to the aging of an asphalt mixture through an HMA plant. This observation was also noted in a discussion of a paper comparing the TFO and RTFO tests (Zupanick, “Comparison of the Thin Film Oven Test and Rolling Thin Film Oven Test”, Association of Asphalt Paving Technologists, Journal, Volume 63, 1994.)

It should be noted that the concerns about treating the recovered asphalt binder as having been aged as if through the RTFO only applies to lab-produced mix and fresh, field-produced mix. It is not a concern for asphalt binder recovered from pavement cores, RAP or RAS. As such, for the sake of simplicity, we would suggest that all recovered asphalt binder should be treated as if it had already been subjected to the equivalent of RTFO aging. The error for fresh, field-produced mix, if any, will likely be minimal.

To determine physical properties and use blending charts as described in “AASHTO R35, Standard Practice for Superpave Volumetric Design for Hot-Mix Asphalt (HMA),” the technologist will first need to determine the “critical temperature,” Tc, of the recovered asphalt binder at high temperature. To accomplish this, the technologist will need to determine the G*/sin ∂ value at two or more temperatures to estimate the temperature where G*/sin ∂ equals 2.20 kPa (the RTFO criterion). The best way to estimate this Tc is to test at two temperatures that are six degrees apart where the G*/sin ∂ value of the higher temperature is less than 2.20 kPa and the G*/sin ∂ value of the lower temperature is greater than 2.20 kPa. In this manner, Tc can be determined by interpolation. However, depending on the stiffness of the recovered asphalt binder, the technologist may have no choice but to extrapolate—particularly if the test temperature where G*/sin ∂ equals 2.20 kPa is expected to exceed 100ºC. Check with your DSR manufacturer to determine if you can test at temperatures in excess of 100¿C.

After testing the recovered asphalt binder at high temperatures, the technologist again needs to decide if further aging is needed to simulate long-term aging using the Pressure Aging Vessel (PAV) before testing at low temperatures. If the recovered asphalt binder comes from a loose mix sample (either lab-produced or field-produced) or a pavement core with less than approximately 2-3 years of aging in-service, then we would recommend that the recovered asphalt binder be subjected to PAV aging at a temperature appropriate for the climate (see AASHTO M320). If the recovered asphalt binder comes from RAP, RAS or a pavement core with more than approximately 2-3 years of aging in-service, then we would recommend that the recovered asphalt binder be treated as if it had already been subjected to PAV aging (i.e., no further aging is needed.)

Note that for blending charts using RAP, “NCHRP Report 452, Recommended Use of Reclaimed Asphalt Pavement in the Superpave Mix Design Method: Technician’s Manual” recommends RTFO aging instead of PAV aging before determining low temperature physical properties. This was originally recommended because the difference in low temperature properties of the recovered RAP asphalt binder after RTFO aging and after PAV aging was small, thereby lessening the need to recover enough material and spend the time required for PAV aging. For RAS, no further aging should be needed.

After the recovered asphalt binder is believed to be in a state representative of an asphalt that has been long-term aged (whether or not any actual lab aging is conducted), it is tested to determine Tc at low temperatures using the Bending Beam Rheometer (BBR). The process is similar to the process described for high temperatures, except that the specification parameters and criteria are different. The same process can be used for the intermediate temperature specification parameter, G*sin ∂, and criterion. For more information on determining Tc, please see the Asphalt Institute’s “MS-26 The Asphalt Binder Handbook.”

After the recovered asphalt binder is believed to be in a state representative of an asphalt that has been long-term aged (whether or not any actual lab aging is conducted), it is tested to determine Tc at low temperatures using the Bending Beam Rheometer (BBR). The process is similar to the process described for high temperatures, except that the specification parameters and criteria are different. The same process can be used for the intermediate temperature specification parameter, G*sin ∂, and criterion. For more information on determining Tc, please see the Asphalt Institute’s “MS-26 The Asphalt Binder Handbook.”

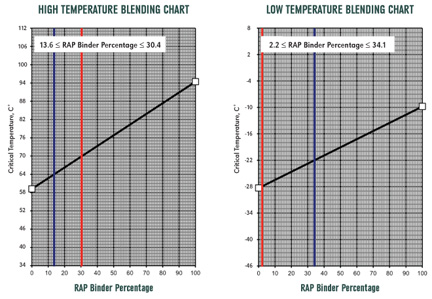

After Tc is determined, blending charts can be used as described in AASHTO R35 to determine either the amount of recycled binder that can be used or the grade of the virgin asphalt binder that should be used.

Contact: Mike Anderson, P.E.