How do the properties of roofing asphalts influence the durability and performance of steepslope residential shingles?

Given that four out of five homes in the U.S. have roofs composed of asphalt shingles, the answer to this question is vital to stakeholders in residential infrastructure. For the insurance industry, the desire to underwrite policies that more accurately reflect quality and performance expectations is a driving factor for more research. For consumers, a clearer understanding of cost-benefit ratios provides economic insight as wind and hail events increase in frequency and severity. And for roofing manufacturers, understanding the relationship between asphalt binder properties and shingle performance has taken on greater urgency as they strive to create a sustainable future for the asphalt roofing industry by producing more durable materials in a competitive environment.

Making up roughly a quarter of the entire shingle composition, asphalt binder plays a vital role in weatherproofing and roof integrity. As with asphalt roadways, the type of binder used in the shingle will impact the overall performance of the structure. Also, like roadways, asphalt shingles age over time through oxidation, leading to stiffening and embrittlement. While the distresses that are experienced on roads (i.e., repeated traffic loading) and roofs (i.e., high-impact hail events) may differ in their respective causes, the resulting failure patterns can be similar…specifically, cracking that can diminish performance over time. Failure events in intricate systems like roadway structures and composite asphalt shingles are often complex and not attributable to a single variable. Because of the large portion of asphalt binder in a shingle, it stands to reason that the properties of the asphalt binder will play a large role in the durability of the shingle; the question is not if changes in binder properties relate to durability, but how much? And can these properties be reliably identified and measured?

The Asphalt Institute has been heavily involved in two parallel projects that attempt to bridge the knowledge gaps related to shingle durability and how roofing asphalts are evaluated. In 2024, the Asphalt Institute Foundation (AIF) published the report for Phase 1 of project AIF 22-03 (“Understanding and Improving the Durability of Asphalt Shingles”). In this initial phase of the project, the Asphalt Institute partnered with Abatech, Inc. and State Farm Insurance to conduct an exploratory study to investigate the relationship between the properties of asphalt binder recovered from aged shingles and shingle performance. Concurrent with this work was a laboratory work plan developed by the Rheology Task Force of the Asphalt Institute Roofing Technical Advisory Committee (RTAC) that ventured to create rheological guidelines and screening tools to aid in the design of asphalts used in impact-resistant shingles. Working in tandem, these two efforts have advanced the understanding of the role asphalt plays in shingle performance, as well as produced measurable properties that will allow for further improvement and innovation in the asphalt shingle industry.

A golden opportunity for durability assessment

Assessing the durability of construction materials can be challenging. Field projects provide consistent and authentic aging; however, these projects often take many years (or decades) to complete, while conditions for producing damage are uncontrolled. Conversely, laboratory conditions provide a controlled setting for aging and damage assessment, but the methods are often more simulative than replicative. Fortunately, State Farm had the foresight and patience to develop a durability program that would leverage the authenticity of field aging and the repeatability of laboratory damage analysis. This 20-year durability program would be the foundation of the first phase of the AIF 22-03 project.

In late 2002, samples of residential shingles were installed on test racks at the State Farm Technological Research and Innovation Laboratory (TRAIL) in Bloomington, Illinois. This “aging farm” was intentionally designed with northern and southern exposures to capture a comprehensive picture of the aging that occurs on steep-slope roofs. Samples consisted of differing brands and types (i.e., laminated, 3-tab, etc.) and included shingles manufactured with both oxidized and modified asphalts. TRAIL also maintained unaged shingle samples from the original 2002 installation, which were kept in storage to minimize oxidative aging.

A portion of the weathered shingles was harvested in May 2008, while other portions of the same shingles remained on the test racks until being harvested in 2022. Samples harvested in 2008 were subjected to a wide range of laboratory analyses at the TRAIL facility, including Underwriters Laboratory (UL) Test Standard 2218, “Standard for Impact Resistance of Prepared Roof Covering Materials.” Impact testing per UL2218 produced a spectrum of shingle damage; when testing at multiple impact points, many shingles reported damage at each impact location (the highest result was 100%), while others showed minimal locations with damage (the lowest result was 7%).

Six of the samples harvested in 2022 and their unaged counterparts were sent to the Asphalt Institute laboratory in 2023 for analysis as part of the AIF 22-03 project. Each sample was broken down using a shredder prior to binder solvent extraction and recovery (ASTM D2172/7906). Recovered binder from each sample was then evaluated for rheological and ultimate (failure) properties using the Dynamic Shear Rheometer (DSR).

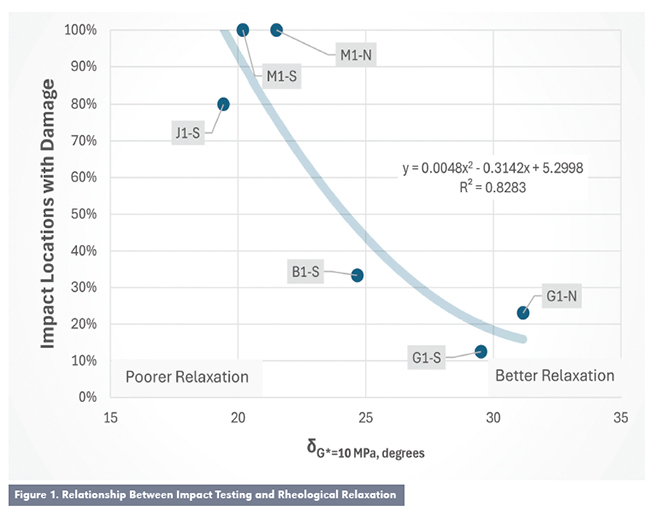

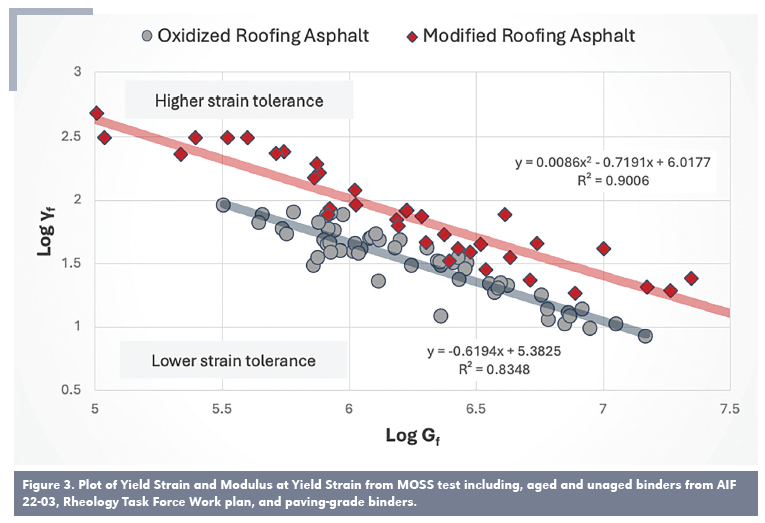

Initial analysis of the data showed a promising relationship between binder rheology and impact performance. Two parameters from master curve analysis were identified as key durability markers: the temperature at which the phase angle (δ) is 27 degrees (Tδ=27°) and the phase angle at a dynamic shear modulus (G*) of 10 MPa (δG*=10 MPa). The Tδ=27° parameter serves as a measure of binder hardness obtained from a region of the master curve where excess stiffness can lead to cracking, while the δG*=10 MPa parameter is a measure of binder relaxation in that same high-stiffness region and is an effective descriptor of the shape of the master curve. Used together, these parameters describe the stiffness of the roofing binder with aging and its ability to maintain ductile properties such that energy can be sufficiently dissipated upon hailstone impact. Additionally, high-strain testing using a modified version of the Binder Yield Energy Test (renamed as the Monotonic Shear Strength Test, or MOSS) was a useful means of discriminating between the ultimate properties of the binders. Metrics from the MOSS procedure, such as yield strain (γf) and yield energy (Ef), were found to be key indicators of material response.

Findings showed that the modified asphalts (shown as B and G in Figure 1) maintained lower stiffness, better relaxation and higher strain tolerance than the standard oxidized asphalts (shown as J and M in Figure 1). Although data points are limited, it is believed that these rheological binder properties are key indicators of how the asphalt binder contributes to the durability of a composite shingle. While these relationships are promising, more data from a broader array of materials is needed to assess the strength of these correlations.

Refining protocols through enhanced laboratory evaluation

As work on the AIF 22-03 project unfolded, the RTAC Rheology Task Force (RTF) was able to evaluate these (and similar) parameters via a separate workstream. Developed by the RTF in early 2023 and supported by Asphalt Institute members, this work plan included a detailed analysis of one oxidized asphalt and five lab-blended modified binders. To simulate oxidative aging, the Pressure Aging Vessel (ASTM D6521) was used at 20-hour and 40-hour test intervals and an aging temperature of 100°C. For each sample, aged (PAV20 and PAV40) and unaged binders were evaluated in a similar manner to the AIF 22-03 project.

Table 1. Material in RTAC Rheology Task Force Work plan

| Reference | Material Description |

|---|---|

| A | Oxidized roofing grade |

| B | PG52-34 + 10% Radial SBS |

| C | PG58-28 + 10% Radial SBS |

| D | PG64-22 + 10% Radial SBS |

| E | PG64-22 + SBS/Post-consumer waste hybrid |

| F | Same as E – but half modification level |

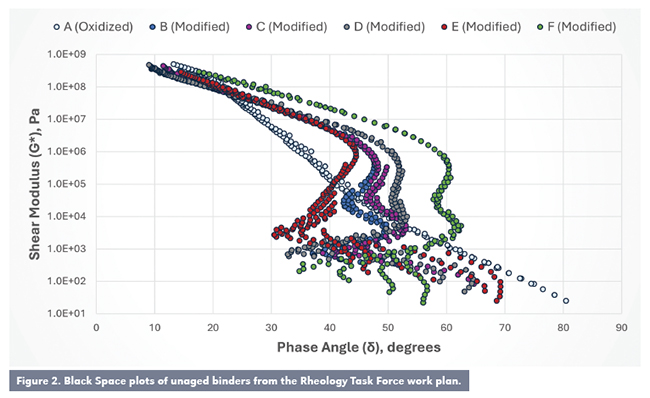

Findings from the RTF work plan were found to align with many of the outcomes of the AIF 22-03 project, with the notable exception that no impact performance data was available. Consequentially, modified materials showed enhanced durability against aging as measured by many of the key rheological metrics identified in the AIF 22-03 report. Additionally, the work plan created an environment of collaboration by which procedures were improved, resulting in draft ASTM methods for the MOSS procedure and a simplified temperature sweep for obtaining the Tδ=27° and δG*=10 MPa parameters. These outcomes are not only a win for the roofing industry but may also have applications in the paving space during a time of increased emphasis on roadway durability.

Figures 2 and 3 show the results of some of the analyses conducted. In Figure 2, the oxidized shingle binder (A) shows a flat curve, while the modified binders (B-F) produce signature “S” shapes. In Figure 3, the strain tolerance gained from polymer modification can be seen in the elevated yield strain in the high stiffness region.

Making a positive impact

With the first phases of the AIF 22-03 project and the RTF work plan completed, the question of what to do next looms on the horizon. It is anticipated that initiatives will continue into a second phase of research; therefore, defining the scope of that research is a matter of first importance for the asphalt roofing industry. Whatever direction this path takes, moving the needle toward sustainable progress will require several key considerations described in the following paragraphs.

• Additional data

Field data collected in the AIF 22-03 project was promising, but more materials and datapoints are needed to flesh out relationships between binder properties and impact performance. A broader, more diverse dataset gives clarity to insurers in targeted underwriting, while enabling roofing manufacturers to better evaluate their own products and methodologies.

• Continued collaboration

Involvement of multiple parties and perspectives was a key aspect for each of these initiatives. If future work is going to make an impact on industry practice, it can only be accomplished in a spirit of collaboration through partnerships between all stakeholders. • Expanded focus While impact damage from hail events was a primary focus in this work, other forms of distress must be considered given the current insurance climate. Wind resistance, granule loss, and scuffing are additional distresses that may provide a more holistic view of shingle durability.

• Technical education

As new data comes to light, analysis evolves, and innovative methods are developed and refined, the education of technical professionals is key. Through training, seminars, and publications, the Asphalt Institute remains committed to working with its roofing members and the industry at large to promote quality at the cutting edge of roofing asphalt technology.

Cooper is the Asphalt Institute Laboratory Manager and Senior Research Scientist. Rowe is Abatech Inc.’s President and CEO.