Accurate material characterization is a vital component in the design, construction and maintenance of the North American roadway network. With the inception of the Performance Grading (PG) system through the State Highway Research Program (SHRP) in the early 1990s, the field of asphalt science took a great leap forward in characterizing asphalt binders used in hot-mix paving applications as it moved away from the Penetration and Viscosity Grading systems to a more scientifically-fundamental scheme, AASHTO M320. Armed with this new purchase specification, agencies could acquire asphalt materials with greater confidence, knowing that they were designed and evaluated within the bounds of a system that employed climatic considerations and fundamental rheological principles.

With a new grading system came an updated laboratory lexicon; complex modulus, phase angle, and m-value were introduced as key terms for defining asphalt binder behavior. Industry partners and organizations committed to technical education spent countless hours and resources seeking to communicate this new era of binder characterization to technicians, engineers, and key decision-makers at each level of agency and industry. Through these efforts, the asphalt community has a much stronger understanding of fundamental binder behavior.

More than 30 years after SHRP, educational efforts continue as new asphalt research has informed novel methods of rheological characterization. Durability parameters like Delta Tc (ΔTc) have begun to crop up in standard specifications across the United States. Measures of binder fatigue, such as the Glover-Rowe Parameter (GRP) have found a comfortable niche in the world of binder research. The proliferation of these newer parameters, combined with growing material complexity through modification and increased material blending, has once again put a spotlight on the need for clarity regarding the concepts and terms associated with modern rheological analysis of asphalt.

A curious case study in blending and rheology

Earlier this year, the Asphalt Institute Laboratory was approached with a rheological conundrum from a client that brought these matters front and center; specifically, material blending and ΔTc. The client was producing asphalt binder blends by adding a material they referred to as “hardpen” (i.e. a hard binder with a penetration value of 8 dmm per AASHTO T 49) to two different polymer-modified binders (a 64E-22 and a 76-22). The laboratory results were surprising: as more hardpen material was added, ΔTc increased (i.e. became “more positive”). To put it another way: as more of the stiffer material was added to the polymer-modified binders, relaxation properties actually improved (Figure 1).

This seeming paradox foregrounds several important questions facing suppliers and agencies today: in a world of increasingly complex binders, how should we be thinking about new rheological parameters like ΔTc? What are the interaction effects of advanced rheological parameters when blending materials? And, maybe most importantly, what do these parameters actually tell us about asphalt binder behavior?

What does ΔTc tell us?

To make sense of this blending case study, the last question must be addressed first: what does ΔTc communicate about an asphalt binder? Simply put, as defined in Asphalt Institute’s IS-240, ΔTc is a relaxation parameter believed to be related to asphalt durability (non-load associated cracking). As an asphalt binder experiences oxidative aging, molecular alteration leads to increased stiffness, reduced ductility and increased brittleness. ΔTc provides a snapshot of binder brittleness in the high stiffness region, specifically as the binder properties change through oxidative aging.

Measured using the Bending Beam Rheometer (BBR) per AASTHO T 313, ΔTc is calculated by finding the critical temperatures (Tc) for Creep Stiffness (S) and m-value (m) at 60 seconds of loading. These values, known as Tc,S and Tc,m, are the exact temperatures at which the specification limits are met (S=300 MPa, m=0.300). ΔTc is determined by finding the difference in these two values (Tc,S – Tc,m); binders with a positive ΔTc value are said to be “S-controlled”, while binders with a negative ΔTc value are said to be “m-controlled”.

It is vital to understand that ΔTc normalizes binder relaxation with respect to stiffness. To the extent that a binder becomes more “m-controlled”, ΔTc tells us that it is showing poorer relaxation properties, or greater brittleness, at a constant creep stiffness (300 MPa). Understood properly, this normalization provides not only a powerful tool for understanding how a binder changes as it ages but also a one-to-one comparison of the relaxation properties of aged materials. By holding stiffness constant, ΔTc evens the relaxation playing field.

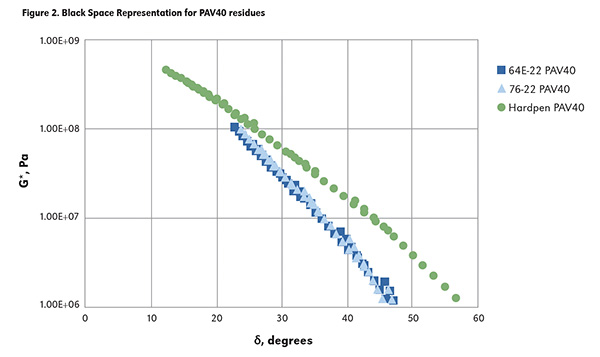

Another way of understanding this type of parameter is to think in terms of dynamic shear modulus (G*) and phase angle (δ) measured using the Dynamic Shear Rheometer (DSR). These two values are analogous to the BBR outputs of creep stiffness and m-value, respectively, despite the different mode of loading (oscillatory shear vs. monotonic bending) and temperature regime (intermediate-high vs. low). Phase angle, like m-value, is a viscoelastic relaxation property that is time and temperature-dependent. However, like m-value with respect to creep stiffness, if phase angle is measured at a constant dynamic shear modulus, phase angle (relaxation) is normalized with respect to stiffness in a similar manner to ΔTc.

A complicated story

Returning to the blending conundrum at hand, we see that these relaxation dynamics are especially evident when plotting G* as a function of δ in the high stiffness region (Figure 2). What is noteworthy in the plotted curves is that, with respect to stiffness, the hardpen binder shows better relaxation (higher phase angle, shifted to the right) than the 64E-22 and 76-22, even up to a G* of 100 MPa (1.00E+08 Pa), roughly the equivalent of 300 MPa creep stiffness measured using the BBR. This is informative for illuminating why the hardpen shows better relaxation at equistiffness conditions, thus marginally improving ΔTc at increasing dosages.

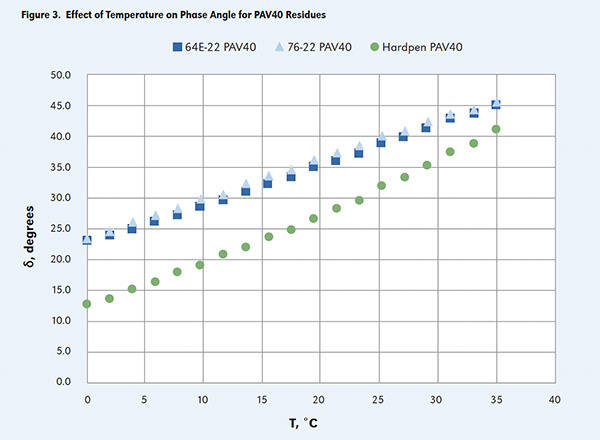

There is, however, another side to this story. While the hardpen binder may show better relaxation with respect to stiffness, the same cannot be said concerning temperature. When comparing the materials at a constant test frequency of 10 rad/s across the intermediate temperature range, the hardpen has a lower phase angle (Figure 3). This temperature sensitivity is notable in the fast rate of decrease in phase angle with decreasing temperature; the gap between the hardpen and the polymer-modified binders increases as temperature decreases.

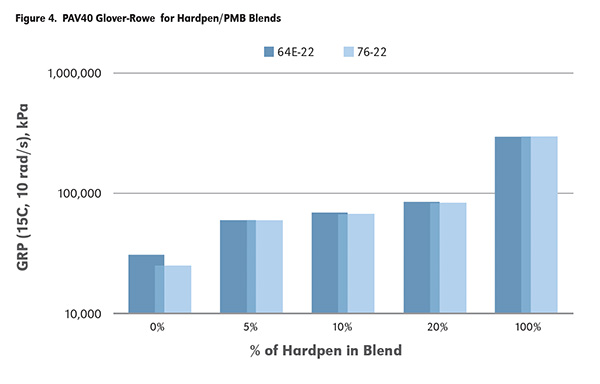

The resulting effect is that temperature-dependent fatigue parameters such G*sinδ or Glover-Rowe measured higher as more hardpen was added (Figure 4). So, while adding this hardpen material may improve durability per ΔTc, the tradeoff is a more temperature-sensitive blend that may reduce fatigue resistance (higher GRP values indicate poorer resistance to fatigue cracking).

Making sense of the madness

It turns out that this curious blending story is not so much about the blending itself, but about the underlying rheology. Both sides of this coin reveal important concepts related to the challenges of binder characterization and formulation. In a world of new rheological parameters, evolving blending practices, and increasing binder complexity, the following four tenants can help industry and agency navigate the new challenges.

1. Definitions matter. One thing is clear from the case study above: there is a danger when definitions overlap. Case in point: stiffness is not the same as brittleness. Put another way: a stiff material (see: hardpen) is not necessarily a brittle material. Oxidation unquestionably leads to increased binder stiffness (S or G*); stresses experienced during thermal or mechanical strain increase with aging. Brittleness, however, is manifested in how a binder relaxes or dissipates those stresses (see: m-value or δ) when measured at equistiffness conditions. ΔTc and other similar parameters capture this ductile-brittle spectrum by normalizing relaxation against stiffness, showing that binders can have different relaxation properties at the same level of stiffness.

2. Blending can be a tightrope balancing act. In the particular case study above, adding the hardpen material improved durability measured by ΔTc, but also increased temperature sensitivity measured in the Glover-Rowe fatigue parameter (GRP). A better understanding of the underlying rheology and the dynamics at play behind these parameters can help formulators produce better binders and promote innovation in asphalt blending. Results can vary with different circumstances.

3. New rheological parameters help paint the full picture. The move to AASHTO M320 was an upgrade, but there are gaps related to non-load-associated durability cracking and load-associated fatigue cracking. Rheological shape parameters like ΔTc or phase angle at constant modulus help fill these gaps and potentially promote more durable pavements. Fatigue parameters like GRP capture sensitivity to loading time and temperature,

thus allowing the user to minimize the effects of binder on fatigue cracking. Both types of parameters are needed for promoting sustainable pavements.

4. What about polymer modification? Properly characterizing polymer-modified binders is a challenge. Parameters like ΔTc may be sound in theory, but they may also inadequately capture the strength and strain tolerance gained through polymer modification because they are determined from small-strain tests. Venturing outside of the linear viscoelastic region may be necessary to show the manifold benefits of polymer modification for asphalt binders.

Cooper is the Laboratory Manager and Senior Research Scientist at Asphalt Institute Headquarters in Lexington, Kentucky.