Have you ever noticed that most paved roads are made of asphalt and asked the question why is that? I’ve actually been asked this question a lot. It normally comes from…well, drivers! Most of the people who’ve asked me this question know that I work in the asphalt industry, and most of them have at least some awareness that the primary alternative paving material, portland cement concrete (PCC) is much stronger and more rigid than asphalt. This begs the question: why wouldn’t we use the stronger paving material to build our roadways? Wouldn’t that lead to longer-lasting roadways? Not exactly, but first, let’s dive into the numbers…

Of the approximately 2.3 million miles of paved roads in the U.S., 94% of them are paved with asphalt. Four states have 100% asphalt-paved roads (Alaska, Maine, New Hampshire, and Vermont); Thirty states have 97% or more asphalt-paved roads, and all but four states have 90% or more asphalt-paved roads (those four at the bottom in terms of percent asphalt-paved roads include Nebraska 88%; Louisiana 84%; Massachusetts 75% and Iowa 62%).

It’s not just that the majority of roads are paved with asphalt, it’s such a high percentage of them that there must be a driving reason (no pun intended) behind why asphalt is overwhelmingly the preferred paving material. There are, in fact, several reasons this is the case. First, anyone with access to the internet can search for this question and get some solid facts about why asphalt is preferred, including:

• Cost-effectiveness (asphalt generally has a lower installation cost compared to PCC, which makes it more appealing to agencies with strained budgets – this is most of them).

• Ease of installation (asphalt can be placed and driven on within the same day, which is incredibly convenient when traffic rarely stops moving; whereas, PCC takes longer to construct and has an extended cure time, which can take many days if not weeks before it can be driven on, depending on the type of cement that is used).

• Traction and safety (asphalt is engineered to provide excellent traction to the driving public, and its black surface reduces glare and reflectivity common to PCC surfaces).

• Recyclability (asphalt is highly recyclable and has been recognized as the most recycled material in the world with an estimated 95% of asphalt waste being reused in some capacity – most of which goes back into new asphalt mixtures). Not only is asphalt highly recyclable, but it also has a long history of accommodating other industries’ recycled materials, including ground tire rubber (GTR), plastics, roofing shingles, waste engine oil, and fibers. Asphalt also utilizes various other by-products of industry, such as bio-oils, additives, and chemicals that may otherwise fail to find a viable end-use application without asphalt roads. In fact, asphalt, itself was once considered to be mostly a waste byproduct of the crude petroleum refining industry with only sparingly few viable applications prior to the automotive boom and the advent of paved roads. Therefore, asphalt is historically a highly circular material that is supportive of various other industries’ reusable materials, with obvious profound benefits in reducing waste and maximizing the use of available resources on the planet over vast length scales.

While all of these points are true and while each has a definite impact on the reason asphalt dominates road construction, I’d like to point to another reason that I believe factors most heavily into the decision-making process of selecting asphalt instead of PCC for road construction.

This one is not quite as easy to find on the internet, because it is a bit more technical in nature. Now, I don’t want this to be an article bashing PCC, because PCC is obviously one of the most innovative materials to ever exist in mankind’s history. There is no other material than steel-reinforced PCC that I’d want used in our bridges or vertical concrete structures. However, one thing that bridges and vertical structures do not have to deal with is the high likelihood of unbound materials shifting beneath the pavement over time.

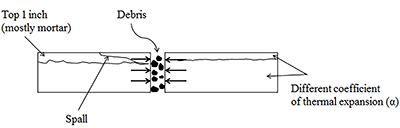

Bridges span a gap and are therefore unaffected by this phenomenon. Vertical concrete structures are generally enclosed and protected from the elements, and therefore, are mostly resistant to this issue as well. However, PCC pavements sit on foundations that are susceptible to moisture, and due to their rigidity, are also very susceptible to movement or settlement. PCC pavements are so rigid, in fact, that joints must be cut in the material about every 10 to 20 feet to avoid the concrete literally cracking to pieces due to expansive and contractive forces. When these joints are cut into PCC, it serves to prevent widespread cracking, but it also introduces a future pathway for water and incompressible materials to get into the joints and underneath the PCC slabs. Damage can include pumping of the subsurface materials and corrosion of load-transfer devices (dowel bars), leading to voids and vertical movement of the slabs under repeated heavy loading. This distress-causing slab movement is known as settlement or faulting and causes a very bumpy ride. An example of this distress is shown in the figure above.

Another prominent issue with PCC pavements is spalling near the slab joints. When incompressible materials become wedged between joints, it leads to a portion of the surface near the edge or corner of the joint cracking and breaking apart contributing greatly to roughness near the surface. Moderate-to-high-severity spalls require immediate action to ensure safe driving for the public and can be difficult to repair with constant traffic demands. The above graphic shows the spall formation mechanism.

If this issue of water and incompressible materials entering PCC joints is to be prevented, it requires meticulous joint sealing practices. I previously worked as a pavement asset manager, and the primary thing we’d tell agencies about their PCC pavements is that you MUST maintain the PCC joints, or you will have major issues with those pavements, including settlement, spalling and sometimes worse. Joint sealing maintenance on a routine basis (every couple of years) across hundreds of miles of roadway is highly impractical, so what ends up happening is that individual slabs begin to shift over time, resulting in the “da dum da dum da dum da dum da dum…” ride quality that we’ve all experienced on these pavements. One example is the east-west stretch of I-10 across southern Louisiana. I dread making that trip every time because the drive is unbearable across certain portions of the interstate due to the poor ride quality of the PCC.

A little more about why this happens with PCC and not asphalt – PCC is very rigid, and although it is built on a foundation just like asphalt, the foundation is not a necessary structural component of the roadway with PCC as it is with asphalt. The foundation underneath a PCC pavement is merely a riding platform. The PCC is so strong, it can carry heavy loads without much need for structural support from the other materials. It just needs a level foundation underneath to work. Asphalt pavements, on the other hand, are constructed with a relatively thin asphalt surface on top of many inches or feet of structural foundation comprised mostly of unbound aggregate base. The asphalt surface does not contain joints and is often impermeable to water and flexes under traffic load, thus transmitting loads throughout the entire structure beneath the surface. In other words, the asphalt pavement is very flexible as it tends to move and rebound without permanently shifting from its original position. Even when asphalt cracks and water enters the cracks leading the water underneath the asphalt, the pavement is not very likely to move significantly from its original position assuming it has proper drainage. This is due to the nature of how the structure functions and flexes. The PCC pavement, on the other hand, has no flex or give to it at all and tends to shift over time under similar conditions.

Asphalt is a flexible pavement material, so one downside is if you put something heavy enough right on top of it and let it sit there for an extended period of time, it could deform or rut.

Of course, asphalt innovations, such as polymer-modified asphalt and more recently highly-modified asphalt are steadily reducing the number of loading cases that asphalt cannot address. The bottom line is that PCC may be stronger by some standards and capable of outliving asphalt in certain conditions, but lifespan isn’t necessarily measured by how long a material can last in isolation, but rather how long the material can serve its intended purpose or functionality in a given application.

With respect to roadways, this means which material can provide the best ride quality to the driving public for the longest period with the least disruption? Asphalt is the clear winner in this regard. The smooth ride is what asphalt is known to provide, and this is easily confirmed in public polling. Asphalt is, in fact, more cost-effective, easier to install, more recyclable, and safer, but perhaps most importantly, it provides a smoother driving surface over time, which is its primary purpose. So now you know why asphalt dominates road construction!

Allen is an Asphalt Institute Regional Engineer based in Florida.