Comparing UL 2218 to IIBHS

In steep-slope asphalt roofing, few tests are more destructive than impact tests. Impact testing is used throughout the industry as a value proposition and a performance metric for roofing materials. For those who live in hail-prone areas, these tests provide key indicators of a shingle’s ability to maintain performance after significant weather events.

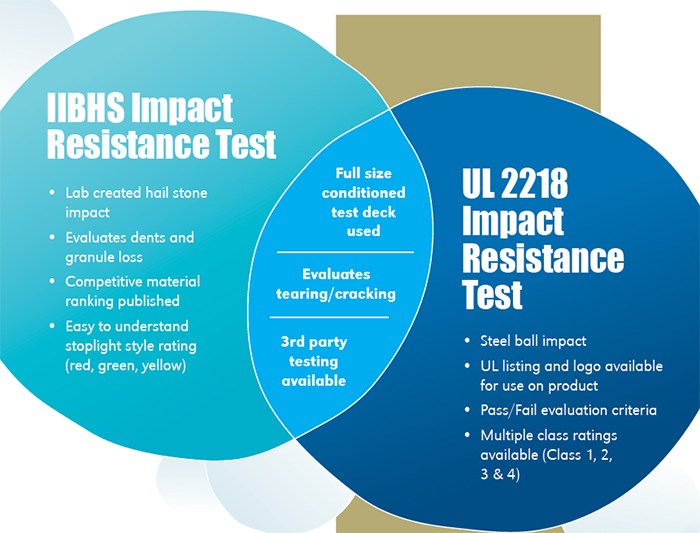

Two major test methods are considered industry standards at present – the Insurance Institute for Business and Home Safety (IIBHS) Impact Resistance Test and the Underwriters Lab (UL) standard 2218 Impact Resistance of Prepared Roof Covering Materials. While both standards offer a way to test impact resistance via impact with a hard and heavy object, there are subtle differences in reporting and performance characteristics. This article will highlight the differences between methods.

UL 2218

UL 2218 testing focuses on the tearing of the roofing material. The test is available in various “classes” (1, 2, 3, and 4). Each class represents a different hail impact resistance with class 4 being the highest class available. In the method, a 1.25-2 inch diameter steel ball (depending on class) is dropped from a height of 12-20 feet (depending on class) onto a prepared and conditioned test deck. The test deck is constructed per manufacturer installation instructions with eight courses of shingles. The deck is impacted in various areas on each course. Once impacts are completed, the deck is deconstructed, and the shingles are evaluated for cracks on the back of the material. Material is bent over a mandrel to ensure all potential cracks are inspected. If no cracks are present, a passing rating for that class of test is obtained. UL 2218 and the class that is tested is often found on marketing materials and product packaging.

IIBHS

The IIBHS Impact Resistance Test takes multiple performance indicators into account in the evaluation of impact resistance. The test involves lab-created hailstones, both soft and hard, being fired at a conditioned test deck via an air launcher. The test deck is installed according to manufacturer instructions and conditioned prior to testing. The deck is impacted in several areas. Once the impacts are completed, the test deck is deconstructed and evaluated for granule loss, dents and tears. Based on the performance in those areas, values and a colored rating dot are assigned. Shingle products are then ranked against competitive products. The final rankings are published online and test results are provided to the IIBHS member companies (home insurers).

Both tests indicate shingle performance after hail events, but what is the difference?

The difference

“The main difference lies within the pass/fail criteria. The kinetic energy is pretty similar so really, it’s the shingle performance evaluation” says Brendan Dineen, who is a Codes Engineer for a national shingle manufacturer.

“The scrutiny that the shingles come under during the IIBHS impact testing is way more stringent” he added. He deals with third-party testing of impact resistance and often attends the testing in person. “The steel ball impact during UL 2218 is shocking, but the smash of the ice ball is more dramatic” he laughs.

Both the IIBHS Impact Resistance Test and the UL 2218 test methods offer insight into shingle performance after hail events. Both methods utilize full-size conditioned test decks, evaluate for tearing/cracking of the shingles, and have third-party testing options available. The UL 2218 test features multiple classes with a clear pass/fail criterion based on a steel ball impact. The IIBHS Impact Resistance Test evaluates more performance areas (granule loss/dents), offers an easy-to-understand stoplight style rating, and ranks manufacturers according to performance, based on a lab-created hailstone impact. The IIBHS method is more comprehensive and stringent but lacks a clear class rating system, making it more difficult for customers to filter and sort shingle options by class category. All in all, taking both methods into account when selecting shingles gives the savvy homeowner peace of mind in hail-prone regions.

Lemmons is a chemical engineer and Research Lab Manager at Malarkey Roofing.